Wire Rope Slings

Wire Rope Cable Slings

Wire rope slings are the perfect choice for heavy-duty lifting and hoisting jobs. Stronger and more durable than nylon and polyester synthetic slings but more economical than chain slings, they can safely handle your load in demanding conditions and high temperatures without breaking your budget.

Their primary advantages are abrasion-resistance and heat-resistance, a combination that's well-suited for a wide variety of applications. Steel cable slings are also quite pliable, meaning they can conform to the shape of a load for a more secure hitch setup.

Sling Cables

Wire rope slings are generally manufactured using either 6x19 or 6x36 EIPS IWRC wire rope that's versatile enough for most lifting jobs.

EIPS stands for Extra Improved Plowed Steel, which has a tensile strength of around 10% greater than an IPS grade, so the same rope diameter has a higher lifting capacity.

Our steel wire rope slings are made with an Independent Wire Rope Core (IWRC) for the ultimate in strength and durability. It's made from steel and can be used in temperatures from -40°F / -40°C to 400°F / 204°C. This core is also resistant to crushing, so it's safer in more demanding environments.

Wire Rope Sling Classifications

6x19 and 6x36 are wire rope classes and are a nominal indicator of the wire rope's construction. The first number represents the number of strands wrapped around the wire rope's core, while the second number is an estimation of the number of wires making up each strand.

Using the table below, you can see that a 6x19 class wire rope has 6 outer strands, and the number of wires making up each strand can range from 15-26.

| Class | Outer Strands | Wires Per Strand |

|---|---|---|

| 6x19 | 6 | 15-26 |

| 6x36 | 6 | 27-49 |

Generally, wire rope slings with a diameter larger than 1" will be 6x36, while those 1" or smaller will be 6x19 for ease of construction.

So what does this mean for you? For most users, either steel cable sling configuration should work for their job. However, if you are looking for extra flexibility and fatigue-resistance in a smaller diameter or added abrasion-resistance in a larger diameter, contact us to learn more about your options!

For extreme flexibility in specialized applications, check out our cable laid slings. Manufactured using a 7x7x7 galvanized wire rope (composed of 7 strands of 7x7 cables), they bend easily and offer superior resistance to kinking.

Wire Sling Rope Eyes

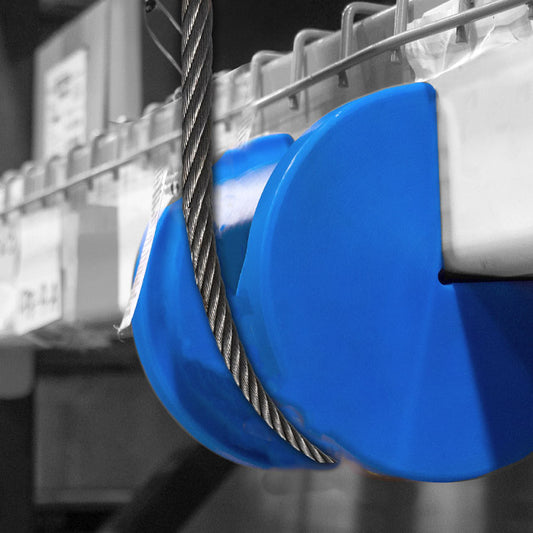

Most of the eye loops on our sling cables are created with a Flemish splice. This eye design makes the most out of the rope's capacity.

The Flemish splice is a mechanical splice where the rope cable is separated into two parts (one part has three strands, the other part has the remaining three strands plus the core), then re-laid back in the opposite direction to form the loop. The ends are then secured with a carbon steel sleeve around the entire area.

Steel Cable Sling Configurations

Our categories of wire rope slings are broken down by number of legs, hardware, and the rope diameter. Each sling is made to order, so custom wire slings are also always an option if you don't see what you're looking for here.

Single Leg Lifting Cables

Sometimes called eye & eye slings because the most popular style has an oval "eye" at each end, these one leg cable slings are rugged, reliable, and a very popular choice among wire slings. Most can be used in all three hitches - vertical, basket, and choker.

Single leg cable slings are available in a variety of styles: Eye & Thimble, Thimble & Thimble, Eye & Hook, Eye & Eye, Sliding Choker, Spelter Socket, Swage Socket, and Cable Laid.

Wire Rope Bridle Slings

Bridle wire rope slings allow for improved balance and load control. Their design includes protective thimbles to reduce rope wear and extend sling life.

With each additional leg, you'll have improved stability and load distribution, but you'll want to balance that with the added setup complexity and the lower maneuverability.

Wire Rope Grommets

If you are working in a low headroom application, wire rope grommets have an endless design that requires less space for lifting or rigging.

Braided Wire Rope Slings

Braided wire rope slings are formed when multiple ropes are braided continuously to form the body of the sling and the eye/eyes into a single fabricated sling. They are excellent for higher capacity lifts, and can conform snugly to a load that's in a choker hitch. Because of the braided design, they also are more resistant to kinking.

Our braided wire rope slings are made in the USA and available in a variety of configurations, including a 3-part braid, 6-part braid, 8-part braid, and 9-part braid.

Custom Wire Rope Slings

If you need a unique solution for your application, request a custom wire rope sling - you can either fill out our online form or get in touch with our sales team. You'll be able to specify construction, length, end fitting, and more!

Import vs. Domestic Lifting Slings

We offer a wide selection of both import and domestic wire rope slings, so it's simple to find the right fit for your application. Regardless of the source, all of our wire rope slings meet the requirements laid out by ASME B30.9.

Our domestic slings are made in the USA with quality components from leading companies like Crosby.

Import slings are a more cost-effective choice, with even more styles to choose from.

Calculating the Length of a Wire Rope Sling

When measuring a domestic wire rope sling with multiple legs, do not include the oblong master - instead, measure the length of the sling leg to the loadbearing point of the hook or eye.

For single-leg slings, measure from the loadbearing point of one eye to the loadbearing point of the other eye / end hardware.

Wire Rope Sling Protection

"Slings in contact with edges, corners, protrusions, or abrasive surfaces shall be protected...to prevent damage." - ASME B30.9 (2021) 9-5.10.4(d)

We carry a number of sling protection options that are compatible with wire rope slings - browse our selection today!

Sling Proof Testing Certificates

All of our slings are inspected, certified, and tagged with metal tags displaying rated capacities by hitch types and angles; diameter or size; and name/trademark of the manufacturer.

If you need proof testing certificates, please request this when you place your order - they are available for a small fee. Each wire rope sling will be pull tested to 2x the vertical rating and officially recorded as proof for governing bodies.

More Lifting & Rigging Supplies

If cable slings are not the best choice for your application, we also offer chain slings, nylon lifting slings, and polyester round slings in a wide range of styles and capacities. As with all of our lifting slings, customization is always an option.

We also carry related products and accessories like anchor shackles, wire rope thimbles, and rigging hooks.

Questions?

Not sure which wire rope sling is right for you? Looking for a bulk pricing quote? Call to speak to one of our product experts today!