Turnbuckles

-

Regular price $7.69Regular priceSale price $7.69You Save 0%Regular price $7.69Regular priceSale price $7.69You Save 0%

-

Regular price $7.99Regular priceSale price $7.99You Save 0%Regular price $7.99Regular priceSale price $7.99You Save 0%

-

Regular price $8.99Regular priceSale price $8.99You Save 0%Regular price $8.99Regular priceSale price $8.99You Save 0%

-

starting at$10.99

-

starting at$17.49

-

starting at$25.99

-

starting at$52.99

-

starting at$67.99

-

starting at$124.99

-

-

-

-

Regular price $5.19Regular priceSale price $5.19You Save 0%Regular price $5.19Regular priceSale price $5.19You Save 0%

-

Regular price $6.59Regular priceSale price $6.59You Save 0%Regular price $6.59Regular priceSale price $6.59You Save 0%

-

Regular price $9.49Regular priceSale price $9.49You Save 0%Regular price $9.49Regular priceSale price $9.49You Save 0%

-

starting at$9.09

What is a Turnbuckle?

A turnbuckle is a device used for tensioning wire rope and other support lines. They are frequently used in rigging, suspension, architecture, and marine applications.

Our turnbuckles are manufactured using galvanized or stainless steel with a full line of end fitting styles. The most popular options include jaw & jaw, eye & eye, hook & hook, jaw & eye, and hook & eye in various sizes.

Learn more about our heavy-duty turnbuckles by watching the video below or by checking out our blog.

How to Use a Turnbuckle

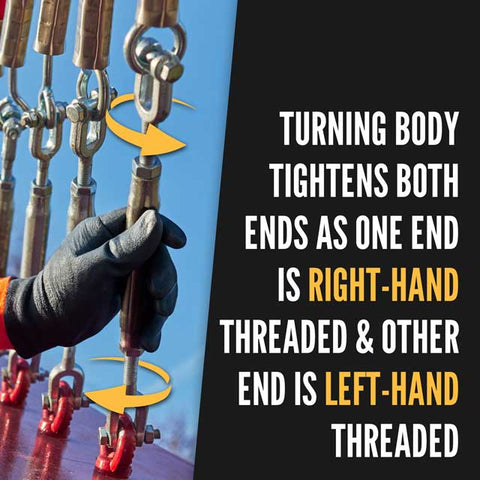

Constructed from a long body with internal screw threads and two opposite-threaded end fittings, this tool lets you easily manipulate your anchor points. Just rotate the turnbuckle body to pull them closer together or push them apart.

Learn more about how to use a turnbuckle on our blog!

NOTE: Turnbuckles are recommended for straight or in-line pulls only.

Heavy-Duty Turnbuckle Construction

Our hot dip galvanized and 316 stainless steel turnbuckles both have high quality hardware fittings. The galvanized finish offers enough corrosion- and weather-resistance to be well-suited for most applications, but stainless steel is the best choice for boat and marine rigging industries. It has increased protection against rust even compared to other stainless steel materials, such as 304 SS.

Shop by Brand

Our wide selection of turnbuckles includes several trusted manufacturers: Crosby and Van Beest. While many customers favor Crosby because they are made in the USA, the Green Pin® brand from Van Beest is ideal if you are looking for a more economical choice. Both options meet federal safety specifications.

Crosby® Turnbuckles

As a leader in the industry, Crosby® takes no shortcuts when it comes to manufacturing turnbuckles - they are all heat-treated and fatigue-rated to ensure strength and and long-lasting durability. Crosby® offers a wide variety of types and sizes to fit your needs.

Van Beest Tension Turnbuckles

Van Beest offers a high-quality rigging product that meets all industry standards. They are easy to spot because they have tinges of the signature Van Beest green color - indicating they are part of the Green Pin® product line. Choose between jaw and jaw, jaw and eye, and eye and eye end fittings.

Turnbuckle Hardware Options

There are a large variety of turnbuckle end fittings available to fit your specific rigging needs, whether you are connecting to wire rope, shackles, eye bolts, lifting rings, or another rigging component. The most common are jaws, eyes, and hooks.

Eye

These solid loop ends have no vulnerable connection points to allow cable to slip through. Most versions offer an elongated eye, which minimizes stress on the components and makes attachment easier.

Jaw / Clevis

These are rigging turnbuckles with wishbone-shaped anchor points. They are fitted with a nut and bolt or pin and cotter assembly, depending on the size. This type of fitting is ideal for situations where the anchor point is closed and will not work with an eye or where the anchor point needs to be secured from slipping off the fitting.

Hook

This turnbuckle hardware is shaped in an open hook. Hooked ends may open the same direction or in opposite directions, depending on your rigging requirements. This fitting offers the quickest option for attachment and release.

Deck Toggle

A "T" shaped bar sits inside a mounting bracket with holes on either side. The deck toggle configuration is often used on bulkheads or for deck fencing.

Drop Pin

Drop pin tensioners have a rotating pin on the end that flips flat into the body of the pin to thread through a hole. They can then be extended perpendicular to the body for a secure hold. This end fitting offers an excellent clean look.

Lag Screw

The threaded lag screw end allows for permanent, secure attachment to your anchor points.

Stub End

These are used where a connecting point is not needed - instead, stub ends can separate or push apart objects.

Swage Stud

Swage stud fittings offer a solid corrosion-resistant endpoint that is threaded to accept wires directly into the fitting and swaged to secure them permanently. This style is used to connect rope ends that don't have an end fitting.

Threaded Rod

Threaded rod turnbuckle hardware end fittings have standard threads that easily form a direct connection to a post or other mounting surface.

Bulk Pricing on Turnbuckles

If you need a large quantity of turnbuckles and other rigging hardware for your project, choose US Cargo Control as your supplier. We can offer competitive bulk pricing, along with all of the advantages of a dedicated account manager. You'll receive personalized support for the entirety of your experience with us.

Learn more about the benefits of working with us, then get in touch!

Find Exactly What You Need

Whether you are looking for cable turnbuckles or a larger assembly, we have a great selection for you to choose from. And if you need help determining the right choice for your application, call our product specialists for assistance.

We also offer additional rigging supplies like wire rope, lifting slings, rigging shackles, and lifting chain to complete your setup.