High Performance Roundslings

High Performance Round Slings

High performance round slings offer an unbeatable combination of strength and low overall weight. Constructed from high performance inner fibers with a protective outer jacket, these slings are a safe and efficient addition to any rigging and lifting setup.

Benefits of HPRS

There are a number of advantages to choosing a high performance roundsling over a traditional wire rope or chain sling.

Lightweight Construction

The first is weight – because they are much lighter than comparable-strength wire rope or polyester options, they are easier to transport, install, and store. You need fewer riggers to manipulate the sling, and there’s a reduced chance of worksite injury.

Load-Conforming

When it comes to fragile or delicate loads, using a wire rope or chain can damage them. Synthetic high performance round slings are softer and conform to the load, so you won’t have to deal with scratches or other damage.

Repairable Cover

If your high performance round sling gets damaged, there’s a chance it can be repaired! Unlike most slings, where damage means the sling is instantly removed from service and a new one is needed, the jacket on high performance roundslings can actually be repaired / replaced. So, if damage is limited to the jacket and the core fibers are unharmed, you might be able to have it repaired. Call us to learn more.

Types of High Performance Round Slings

There’s a wide variety of materials used to make both the covers and the jackets of high performance round slings. Each offers their own benefits, but all are UV- and abrasion-resistant.

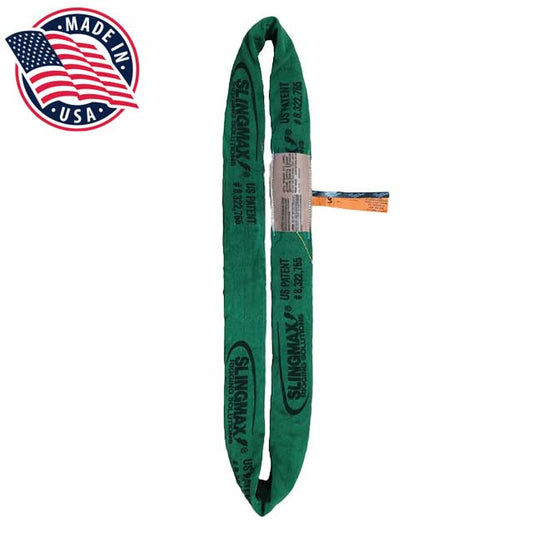

UHMPE Round Slings

Constructed from Ultra High Modulus Polyethylene with a double-layer polyester cover, UHMPE round slings have 75% less elongation than polyester round slings, and they won’t rot, mildew, or corrode.

Twin-Path® Slings

Made with two independent core fibers, Twin-Path slings have a Covermax® jacket that’s more than four times more abrasion-resistant than a polyester cover. Available in both endless and eye & eye styles, these high performance round slings are well-suited for applications like bridge construction and wind turbine installations.

Sparkeater® Slings

Twin-Path high temperature Sparkeater slings can be used in environments with temperatures up to 300˚F (149˚C). This enhanced heat-resistance makes them perfect for applications like off-shoring petroleum testing and pyrotechnic display-related lifting.

Single-Path Slings

Single-Path slings offer many of the same benefits as Twin-Path slings but at a smaller footprint. With only one fiber path, they are lighter and easier to store, but with lower lifting capacities.

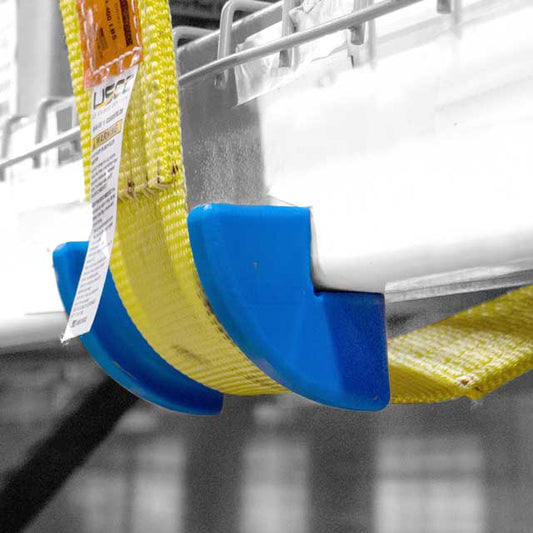

HPRS Sling Protection

"Slings in contact with edges, corners, protrusions, or abrasive surfaces shall be protected with a material of sufficient strength, thickness, and construction to prevent damage." - ASME B30.9 (2021) 9-5.10.4(d)

Prevent high performance round sling damage during lifts by exploring our line of sling protection today.

Questions?

Give our product experts a call today if you need more information on our high performance round slings. They can help you decide what type of sling would work best for your application, and can even help you place an order.

Make sure you’re fully prepared by checking out the rest of our lifting and rigging supplies, including rigging hardware, lifting beams and spreader bars, and more.