Snatch Blocks & Wire Rope Pulleys

Block and Tackle Pulleys and Snatch Blocks

Snatch blocks and cable pulleys are common lifting mechanisms used for rigging and lifting applications. These versatile tools reduce the amount of force required to move or lift heavy objects, letting you easily multiply your lifting power, redirect loads, and reduce strain on your lifting system.

Commonly found in cranes, hoists, towers, and overhead rigging systems, they’re essential in any application where guided movement and control of heavy loads are required.

Types of Block & Tackle Pulleys

While many use "snatch block pulley" to refer to both snatch blocks and cable pulleys, this term is actually a combination of two distinct pieces of equipment. These products can generally be used interchangeably - as they are both designed to temporarily redirect the load path or reduce strain during lifting and pulling tasks - but are best-suited to different applications.

What is a Snatch Block?

A snatch block comes with a metal plate that is designed to open, allowing for easy threading of your wire rope or cable. This eliminates the need to thread the entire cable through, and is especially useful in applications where the line is already fixed on both ends or when mid-line access is needed.

By integrating a snatch block into your rigging setup, you can effectively double or triple your pulling power. They are able to swivel and pivot under load, which helps redirect pulling angles and reduce lateral stress for safer and more efficient lifts.

Snatch Block Options

- Snatch Blocks with Hook: Quick to attach and remove, excellent for field adjustments and towing operations.

- Snatch Blocks with Shackle: Provides a more secure connection, preferred for permanent or high-load installations.

- Swivel Eye Snatch Blocks: Reduces rope twisting and misalignment during use.

What is a Wire Rope Pulley?

A wire rope pulley block, on the other hand, stays closed during the reeving process. It's a wheel with a grooved rim, designed to guide and support the movement of wire rope or cable. These devices are used to lift, move, or redirect loads with minimal friction. Since they typically don’t have a side-opening feature, these lifting pulleys are better for static or permanent installations.

Cable Pulley Options

- Fixed Eye Pulleys: Ideal for static or consistent directional use.

- Double-Sheave Pulleys: Designed for compound rigging where additional lifting capacity is needed.

Advantages of Using a Snatch Block / Cable Pulley

For use with everything from sailboats to ATVs, these blocks can be a real workhorse. Given it's name because it contributes to or "snatches" the mechanical force of pull, it offers a unique combination of power and flexibility:

- Improved Power: When used with a winch, a block lets you pull or lift heavy objects by "breaking" the pull span between the object and the winch. This cuts the direct pull load in half, which doubles the amount of weight your winch can pull.

- Directional Control: Easily change the direction of your pull without repositioning the anchor or the load.

- Reduced Equipment Strain: Lessens wear and tear on winches, ropes, and other rigging system components by distributing the load more efficiently.

Snatch & Pulley Block Rigging Applications

We offer snatch blocks and pulleys in various designs and sizes, including stainless steel blocks, square blocks, single and double pulleys, swivel blocks, and more, along with the compatible wire rope - perfect for a wide variety of industries.

Common applications include forestry and logging, construction and infrastructure, marine and dockside, and utility work.

Choosing a Snatch Block / Cable Pulley Block

With so many different variations, sizes and weight limitations, it's important to know what to look for. There are a variety of factors to keep in mind when choosing a block for your rigging needs:

Cable Pulley Working Load Limit

Check the Working Load Limit (WLL) of both the snatch block / wire rope pulley and the wire rope. If the WLL of the block is not compatible with the WLL of the rope, it can create a dangerous situation if either one should fail.

Note: Know your numbers. Because a pulley block can cut the direct pull load in half, choose one that has a rating of double the pull of the winch you'll be using with it.

Snatch Block Size

Coordinate the size of the sheave in the block to the diameter of the wire rope. If the wire rope is too large for the sheave, the block can crack. Generally, the wire rope-to-sheave size ratio should be 12:1 in order to hold the wire properly while under load.

Heavy Duty Snatch Block Styles

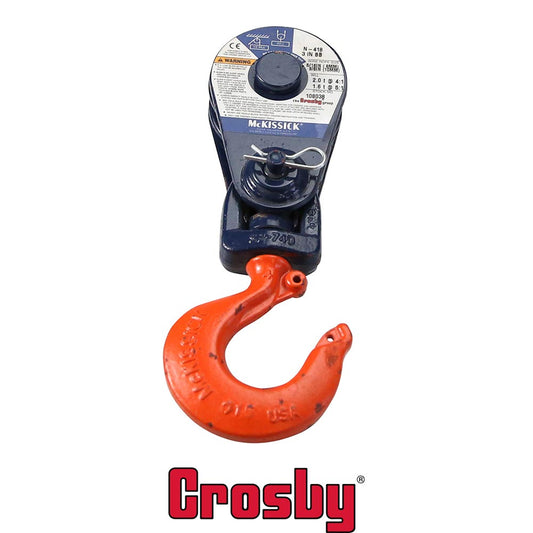

Along with the above factors, the wire rope pulley design is also important. We carry a variety of styles of heavy duty snatch blocks / lifting pulleys, including those with a hook end fitting, a shackle end fitting, and a swivel mechanism. We even offer a selection from Crosby McKissick, one of the most trusted manufacturers in the industry.

Material / Finish

Choose a stainless steel finish for corrosion resistance in marine or outdoor environments.

How to Use a Snatch Block

Using a snatch block is simple if you follow our directions below. As a reminder, if you have a pulley instead of a snatch block, a pulley does not open and steps 1 and 3 are unnecessary.

1. Open the Sheave's Casing

The first thing you will need to do is open the snatch block casing, which will then give you access to the sheave. Depending on the type of snatch block you have, this step will be slightly different. Some casings are secured with screws, while others are secured with wire pins.

2. Reeving

The next step is called reeving, which is just another term for threading the wire rope around the sheave. You will want to wrap it around the sheave several times to ensure that it will stay in place.

3. Replace the Sheave's Casing

The final step is replacing the metal casing, which can be done by undoing what you did in step one to remove it.

Maintenance Tips for Safe Operation

- Inspect Before Use: Always check for signs of wear or damage, including the side plates, sheave, and pins.

- Lubricate Bearings: Keep swivel and sheave points properly greased to maintain smooth operation.

- Stay Within Working Load Limits: Never exceed rated working load limits or mismatch pulley size to rope diameter.

- Clean and Store Properly: After use, clean and store in a dry place to avoid rust.

Questions About our Snatch Blocks & Lifting Pulleys?

Choosing the right pulley block and all the equipment to go along with it can be confusing. If you have any questions about using / choosing wire rope blocks, figuring out the necessary working load limits, etc., contact one of our sales specialists. They can help you find just what you need to get the job done safely.

Custom assemblies are also available if a standard wire pulley or snatch block won't meet your needs.

Looking for more rigging equipment and hardware? Browse our selection of wire rope, material handling products, load cells, and more.