Synthetic Lifting Slings

Synthetic Slings

Synthetic slings are lifting slings made from a synthetic material, such as nylon or polyester. Generally more cost-effective than a chain sling or wire rope sling, they are an excellent choice for a wide variety of general lifting applications.

They are lightweight and flexible, making them easier to handle and store than slings made from other materials, and synthetic slings conform to the shape of your load, offering protection for fragile cargo.

Synthetic Webbing Slings

A web sling made from nylon has more stretch than a polyester sling and is also available in a wider variety of configurations. Made in the USA from industrial-grade webbing, nylon lifting slings have been treated to improve abrasion-resistance.

Configurations include eye & eye, twisted eye & eye, endless, triangle, triangle choker, reversed eye, attached eye wide, and continuous eye wide.

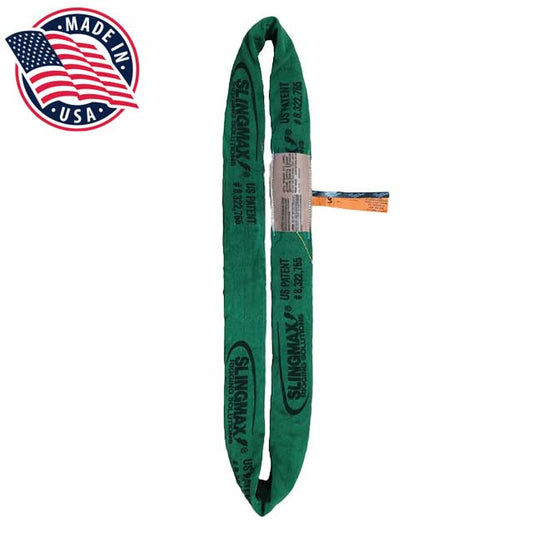

Synthetic Round Slings

Synthetic roundslings are constructed from core yarns covered with a protective jacket. This rugged woven fabric sleeve not only protects the sling's fibers, it adds a layer of protection to items being lifted.

Available in either an endless or eye & eye configuration, they have very little stretch compared to nylon.

Polyester Roundslings

With both polyester core fibers and a polyester jacket, polyester roundslings are resistant to mildew and rot and are unaffected by bleaching agents or common acids.

They are color coded by capacity for quick identification and can be used in all three hitch types: vertical, basket and choker.

High Performance Roundslings

High performance roundslings are similar to polyester roundslings but with higher hitch capacities. This is due to the inner fibers used in their construction.

They offer strength comparable to wire rope and chain slings, but at a much lower weight.

UHMPE Roundslings

UHMPE HPRS have core fibers made from Ultra High Modulus Polyethylene with a polyester cover. They are rot-, mildew-, corrosion-, and UV-resistant for superior performance.

Twin-Path® Roundslings

Experience unmatched durability with our Twin-Path roundslings. Crafted with two independent core K-Spec® fibers, these roundslings feature a Covermax® jacket that boasts over four times the abrasion resistance of a standard polyester cover. Ideal for demanding tasks such as bridge construction and wind turbine installations, these roundslings are available in both endless and eye & eye styles.

Single-Path Roundslings

For those seeking a more compact and lighter lifting solution, our Single-Path roundslings offer the same quality and reliability as their Twin-Path counterparts. With a single K-Spec® fiber path, these roundslings are easier to store and transport, though they do come with slightly lower lifting capacities.

Sparkeater® Roundslings

When extreme heat resistance is paramount, look no further than our Twin-Path Sparkeater high-performance roundslings. Engineered to withstand temperatures up to 300˚F (149˚C), these roundslings are perfect for applications such as off-shore petroleum testing and lifting needs related to pyrotechnic displays. Their core yarn is made from Aramid.

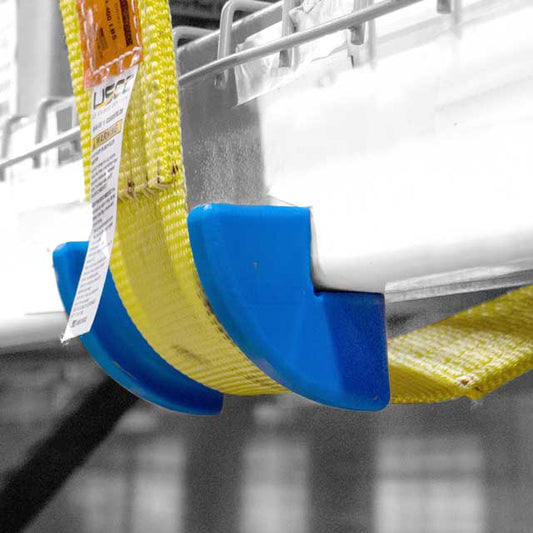

Synthetic Lifting Sling Protection

"Slings in contact with edges, corners, protrusions, or abrasive surfaces shall be protected with a material of sufficient strength, thickness, and construction to prevent damage." - ASME B30.9 (2021) 9-5.10.4(d)

Don't forget sling protection for your synthetic sling - explore all of our options, including cut-resistant CornerMax® sleeves.

Questions?

Our team of products experts is standing by to help! Call today for assistance in choosing the best sling for your application, as well as help placing an order.