Twin-Path® Slings

Twin-Path High Performance Roundslings

Constructed from two independent K-Spec® load-bearing fiber core yarns with a protective Covermax® jacket, TPXC or Twin-Path slings offer higher working load limits, superior performance, and a extended product lifespan.

Load-tested to 200% of capacity, lightweight, and stronger than similarly-size wire rope or chain slings, Twin-Path® slings are well-suited to a wide variety of applications. They've been successfully used in bridge construction, turbine installations, and more.

Why Choose a TUFXKS Twin-Path Sling?

There are a number of advantages of choosing a Twin-Path sling over other sling types like chain, wire rope, or nylon.

One consideration to keep in mind is that these slings should only be used in temperatures between -40˚F (-40˚C) and 180˚F (82˚C). If you are looking for a high-temperature sling, our Twin-Path® Sparkeater® slings can be used in temperatures up to 300˚F (149˚C). While these are constructed using the same design as our standard Twin-Path® slings, Sparkeater® slings are made from different materials, so not all of the information below applies.

Long-Lasting

The load-bearing core yarns using in Twin-Path slings were found to be the longest-lasting on the market, making these slings a smart addition to any rigging or lifting application.

Even the sling design helps to minimize the chances of sling failure - since there are two separate fiber paths with their own connection between the load and the hook, if one fails, the other can help prevent catastrophic failure, allowing the operator to lower the load back to the ground. This won't be the case in all situations, depending on the application and the load, but it's still an improvement to worksite safety.

Lightweight

Measured against a comparable-strength steel sling, a Twin-Path sling is only 10% of the weight! This not only makes these slings easier to transport and set up, but it also reduces the chances of lift-related injuries.

Abrasion-Resistant

The core yarns are protected by a Covermax® jacket. This cover is made from a double layer of industrial-strength nylon which offers more than four times the abrasion-resistance of polyester jackets.

The Covermax® jacket comes with a inner red inspection cover so it's easy to spot damage.

Durable

Twin-Path slings are non-conductive, non-corrosive, and UV-resistant. They also have excellent tension fatigue, are not damaged by most chemicals, and are unaffected by water (both salt and fresh).

Low Elongation

At rated capacity, Twin-Path slings experience only a 1% elongation, perfect for low-headroom and other applications where precision is key.

Repairable

Slings are expensive, and replacing damaged ones can be a big hit to your budget. Depending on the type of damage, these slings may be repairable. This is typically the case when only the Covermax® jacket has been damaged and not the core yarns.

Load-Conforming

Unlike chain and wire rope slings, Twin-Path sling flexibility allows them to conform to the load, preventing damage to more fragile items.

Check-Fast® Inspections

Each sling comes with an early-warning Check-Fast® inspection system, which includes a visual indicator that makes it simple to identify when a sling has incurred fiber damage, fiber-on-fiber abrasion wear, and more.

This system works via a third fiber path with a link designed to fail above the proof load but before the sling reaches its maximum capacity. When this link fails, it pulls at the visual indicator, hiding it from view.

If you do not see the visual indicator, the sling should be removed from service immediately and sent back to the manufacturer for potential repair. Call us to learn more.

Note: This is not a replacement for a standard inspection. Thorough inspections conducted by a qualified professional should still be completed regularly.

Twin-Path Sling Types

The two styles of TXPC slings include endless and eye & eye. Both are designed to allow for wear point adjustments between each use, which extends the service life of the sling. Choosing between the two styles is usually a matter of personal preference, as each can be used in all three hitch types.

Both styles should be measured by laying them out flat and measuring from sling tip to sling tip.

Endless

Endless slings are a loop and offer more hitch versatility.

Eye & Eye

Eye & eye slings include a sleeve that goes over the body of the sling, creating eyes for easier setup and manipulation.

The sleeve on this sling can actually be removed and reinstalled, changing the wear points.

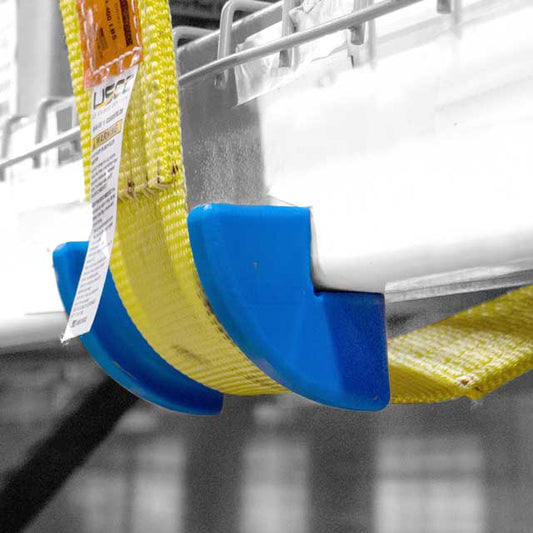

Twin-Path Sling Protection

"Slings in contact with edges, corners, protrusions, or abrasive surfaces shall be protected with a material of sufficient strength, thickness, and construction to prevent damage." - ASME B30.9 (2021) 9-5.10.4(d)

While Twin-Path slings have remarkable durability, sling protection is still recommended during use. Additionally, you should not twist this sling past 180 degrees.

Questions?

Not sure which Twin-Path sling is right for you? Call to speak to one of our product experts today for assistance.

Be sure to check out the rest of our lifting sling selection as well, including Single-Path endless slings and high temperature Sparkeater® slings.