Turnbuckles 101

Turnbuckles are an essential component of many rigging applications, offering the flexibility and security you need to safely configure tensioning assemblies.

What is a Turnbuckle?

A turnbuckle is rigging hardware used that's used for adjusting the tension in wire rope, cable, and other support lines. Its unique design allows you to incrementally apply or relieve tension as needed.

Jump to the Information You Need

View / Download this Document as a PDF

How Do Turnbuckles Work?

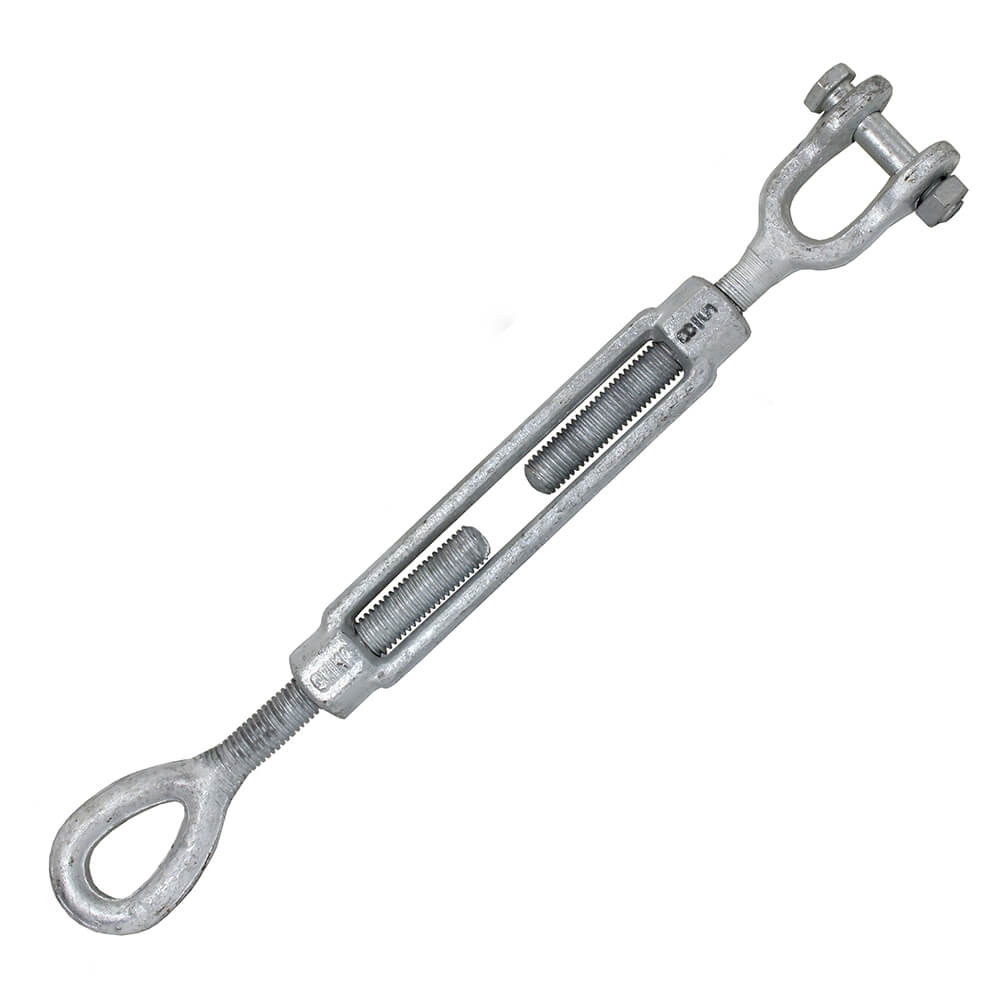

To understand how a turnbuckle works, you first need to understand its parts. A standard version consists of just three parts:

- A long, threaded body. Each side has different internal threading, allowing you to turn the body and adjust the tension without affecting the positioning of the end fittings.

- Two threaded end fittings. The end fittings you choose will vary based on your application. We offer jaw & jaw, eye & eye, hook & hook, eye & jaw, and hook & eye turnbuckles in a variety of sizes.

What Are Turnbuckles Used For?

You can find these items in a wide range of applications. Examples include fencing, bridges, boating, construction, and more.

In each example, turnbuckles provide necessary support to keep everything functioning as it should – whether that's keeping fence wires taut so livestock can't get out or a keeping a cell tower or suspension bridge standing.

How to Use a Turnbuckle

Turnbuckles are designed to be easy to use. To install, simply unscrew the end fittings, attach one to the anchor point, one to the cable line, then tighten as needed by turning the turnbuckle to screw the end fittings back in.

This hardware can be tightened by hand, allowing for quick adjustments in the field, but you can also use a screwdriver, wrench, or other tool to speed up the process.

Looking for more information? See our in-depth installation instructions.

What are Turnbuckles Made Of?

Turnbuckles are made from either galvanized or stainless steel.

Both offer heavy-duty performance and reliability. The main consideration is corrosion-resistance – stainless steel is more resistant than hot-dipped galvanized steel, making it ideal for marine applications.

Choosing the Right End Fitting

While there are a wide range of end fittings available, we'll focus on the three that are most popular. The types are named for their end fittings so it's easy to locate the style you want – for example, an eye & eye turnbuckle has two eye end fittings, while a jaw & eye turnbuckle has one jaw end fitting and one eye end fitting.

Eye End Fittings

Eye end fittings are solid loops, offering a permanent connection with no weak points.

Jaw End Fittings

Jaw end fittings come with a nut and bolt or pin and cotter assembly, perfect for applications where you can't use an eye end fitting but still need a secure, long-term connection.

Hook End Fittings

For short-term rigging situations, consider a hook end fitting. These are much quicker to attach and release than other styles.

Turnbuckle Sizes

There are two sizes that matter: the thread diameter and the take-up or body length.

The thread diameter is directly correlated with the working load limit – the stronger you want your turnbuckle to be, the greater the diameter you should choose.

The body length is the difference between when the turnbuckle is "open" (the end fittings are fully extended) and "closed" (the end fittings are fully retracted). In other words, it refers to the amount of tension the turnbuckle can take up, making it an essential measurement to know.

Measuring a Turnbuckle

The diagram below shows you the different import measurements. "A" is the thread diameter and "BB" is the body length.

Inspecting a Turnbuckle

To ensure the quality of your turnbuckles hasn't been compromised, you should inspect them before each use. These visual checks are essential for worksite safety.

Examples of reasons to remove an item from service include excessive corrosion, gouging, or other similar deterioration; deformed load-bearing components; and heat damage.

More Articles You May Like

How to Tell When It's Time for New Rigging Gear

Screw Pin vs Bolt On Shackles: What's the Difference

Questions?

For any questions on turnbuckles or our other lifting and rigging products, contact one of our product experts today!