Single Leg Wire Rope Sling

Single Leg Wire Rope Slings

Our single-leg wire rope slings come in a variety of ends suited for various applications. Each eye is formed using a flemish eye splice. Flemish eye wire rope is incredibly efficient in maintaining the working load limit compared to other termination methods. It is extremely versatile and can withstand harsher conditions.

Because wire rope lifting slings can be used in a range of industries, they can be manufactured in a range of styles. The most common include:

Eye & Hook Sling: A thimbled hook on one end creates a quick grab option for an excellent multipurpose sling.

Thimble & Thimble Sling: Similar to a traditional eye & eye sling but fitted with protective thimbles on each eye. A thimbled protects the eye from pressure, wear, and tear, to extend the working life of the sling.

Eye & Thimble: Cable sling design is manufactured with two eyes and a protective thimble on just one end.

Sliding Choker Wire Sling: Sliding choker wire rope slings are made of 6 x 19 EIPS wire rope and have a sliding choker hook between the two eyes that slides from one end to the other for easy hook-up. Sliding wire choker slings feature a regular eye for the top portion of the lifting sling and a thimbled eye for the portion of the sling that loops back to attach to the sliding hook. This helps prevent wear and tear on the sling eye by protecting the steel cable rope from rubbing on the hook. Our sliding wire rope choker slings are also available with a latched choker hook by special order.

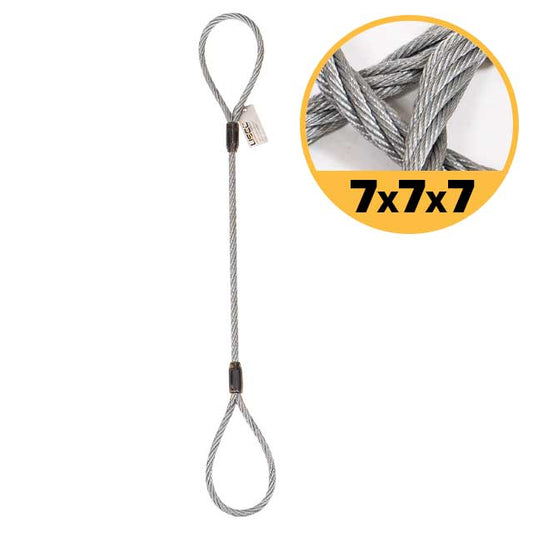

Ultra Flexible Cable-Laid Sling: Cable-laid wire rope slings are manufactured using an ultra-flexible 7 x 7 x 7 galvanized aircraft cable to offer more flexibility than a standard steel wire cable sling. Though the cable-laid sling is weaker in strength than the standard wire rope, it offers excellent corrosion resistance. Our standard cable-laid metal slings have eyes on both ends but other fittings are also available, including thimbles, hooks, crescent thimbles, and slip-thru thimbles to create the custom steel strand lift sling you need.

Quality and Compliance

- Proof Testing Certificates: Available upon request for a nominal fee, proof testing certificates verify that the sling has been pull-tested to twice its vertical rating, providing documented assurance of its strength and performance.

- Compliance Standards: Our wire rope slings meet or exceed ASME B30.9 and OSHA 1910.184 standards, ensuring reliability and safety in all lifting operations.

- Metal Tag: Each sling is thoroughly inspected, certified, and tagged with metal tags displaying capacity, care instructions, and operational guidelines.

Calculating the length of a wire rope sling

When measuring single-leg slings, measure from the load-bearing point of one eye to the load-bearing point of the other eye/end hardware.

Custom Orders

Need a custom solution? We offer custom wire rope slings to meet your specific requirements. Simply fill out our online form or call us today to provide your specifications and receive a personalized quote.

Order Now

Ready to order your single-leg wire rope slings? Purchase through our website or call us for assistance. We will provide personalized quotes, help place orders, and answer any questions you may have.

Complete your rigging and lifting setup by checking out the rest of our lifting and rigging equipment - including sling protection, shackles, and lifting beams and spreader bars.