Chain Slings & Lifting Chains

Lifting & Rigging Chains

Chain slings and lifting chain are ideal for applications when extra strength and durability is required. Not only are chain slings more durable, temperature-tolerant and cut-resistant than web slings or polyester round slings, they are also very versatile.

Lifting Chain Grades

Our alloy steel chain slings come in two grades: 100 and 120. Both are approved for overhead lifting and meet or exceed the NACM, ASTM, and OSHA U.S. standards for lifting chain.

Grade 100 Chain Slings

Grade 100 is becoming the industry-standard grade for chain sling manufacturing. Safe for overhead lifting, this alloy chain features exceptional strength and fatigue-resistance. It's 25% stronger than Grade 80, the next level down.

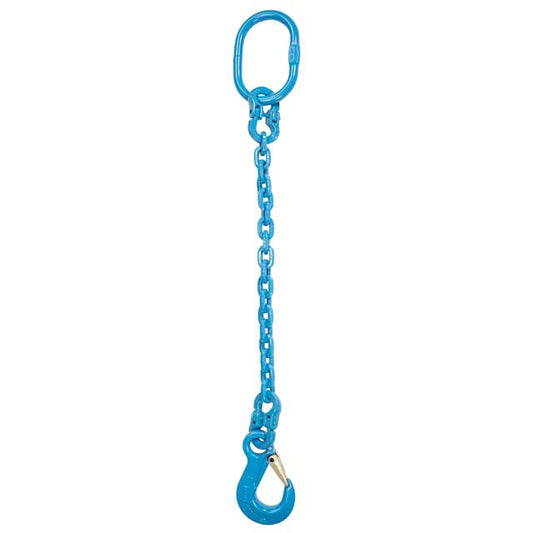

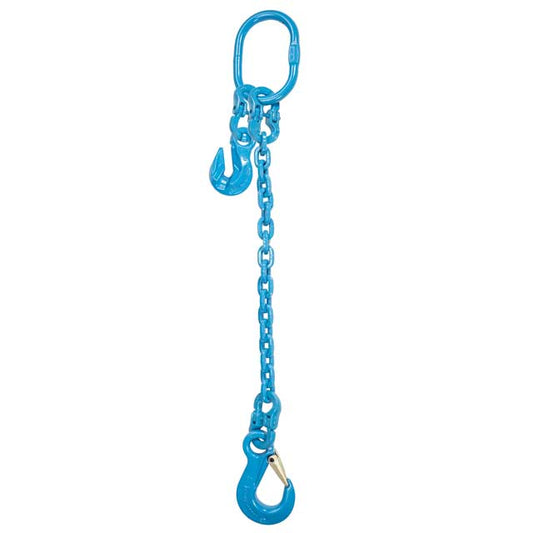

Grade 120 Chain Slings

Grade 120 chain is our premium option and is 50% stronger than Grade 80 chain. The unique square links and high alloy steel construction are ideal for most overhead lifting applications, and the added strength means you can lift more with a lighter sling.

This is most beneficial when it comes to worksite safety and efficiency. You'll need less riggers to set up the sling, and it's easier to work with.

Chain Sling Brands

We offer several trusted brands for you to choose from, including domestic brands, Pewag, and KWB. All of our slings are expertly assembled by US Cargo Control at our Iowa-based facility.

Domestic

Our domestic chain slings are used with a combination of Peerless, CM, and Crosby components. Crosby has been a leader in the rigging and lifting industry for years and takes no shortcuts when it comes to manufacturing lift chain and rigging hardware, while Peerless and CM have long been trusted names in chain manufacturing. The domestic chain slings we sell are manufactured right here in the USA with 100% USA-made components.

Gunnebo

Gunnebo chain slings combine multiple functions into fewer components for faster, safer, and more efficient lifting. Built by US Cargo Control with premium European parts, these slings are ideal for high-demand lifts.

KWB

KWB slings have a signal violet varnish coat and a heavy powder coating that helps with corrosion resistance. KWB is a Pewag company, based in Europe.

Pewag

Pewag grade 120 lifting chains are light blue for easy identification.

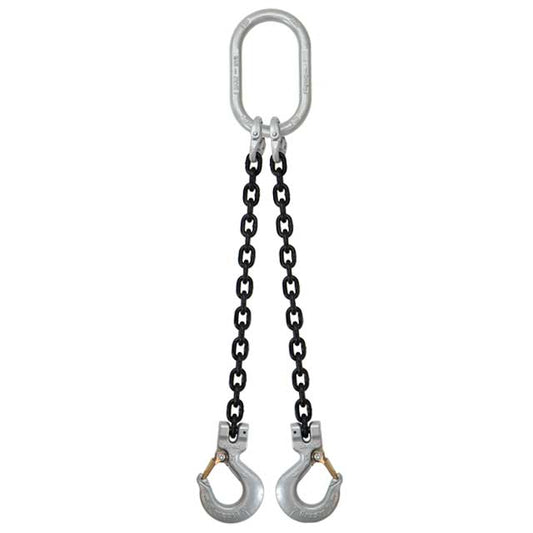

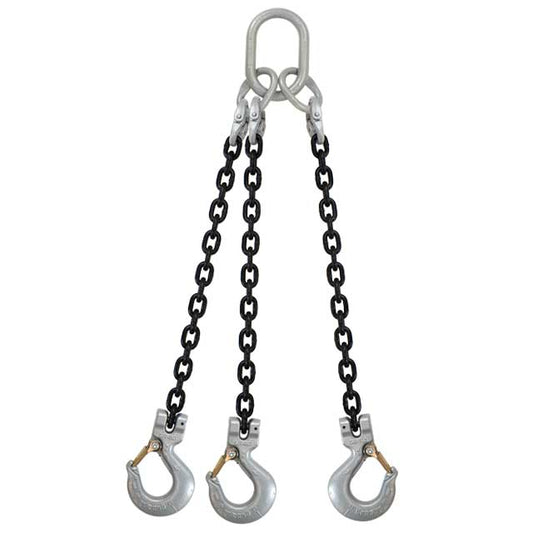

Chain Lifting Sling Types

We sell two main types of slings: standard and adjustable, both of which can be configured a number of ways to ensure they meet the needs of the lift. Several different options are available, including number of legs, the size of the chain, and the length of the chain.

Custom options for various end fittings are also available: just fill out our custom chain slings form or call our sales team.

Standard Chain Sling

Features one, two, three, or four lengths of chain, each with a master oblong link at the top, and your choice of hooks: foundry hook, grab hook, sling hook, or self-locking hook.

Adjustable Chain Sling

Designed with the same leg configuration as a standard chain sling, but also includes an adjustable fitting. This enables the operator to shorten the length of the leg as needed.

Browse all of our available adjustable chain sling styles.

How is the Reach of Lifting Chains Calculated?

A chain sling’s reach is the measured length from the load-bearing point on the sling’s master link to the load-bearing point on the opposite end when the sling is pulled taut.

End Fitting Options

The varied customization opportunities are what makes industrial chain slings so versatile and appropriate for a wide variety of lifting jobs. Most are fitted with either a foundry, grab, sling, or self-locking hook. Adjustable slings feature an additional length adjusting mechanism.

There are several common sling hooks / end fittings to choose from:

- Sling hook: These large throat hooks are typically self-locking to avoid disconnecting.

- Self-locking hook: These hooks are designed to pivot in the middle and lock when lifting pressure is applied. They cannot be opened while lifting.

- Foundry hooks: Extra-large throat hooks used in unique situations that require a larger opening to manage loads.

- Grab hook: They have a small throat that attaches to the chain by slinging over the chain in-between links.

- Oblong master link: An oblong-shaped ring used at the top of chain slings.

Bulk Alloy Sling Chains

We also sell bulk grade 80 chain, grade 100 chain, and grade 120 chain.

Chain Sling Safety & Inspection

When working with lifting chains, proper use and care is essential for ensuring workplace safety.

- Always use within posted working load limit

- Distribute loads evenly - an unequal load on one leg can create a dangerous situation and damage the sling

- Rapid or sudden stops, impacts, and lifts should be avoided

- Do not allow a chain length to be twisted or tied into a knot

- Load hooks should never be tipped or pointed - a latch should never support a load

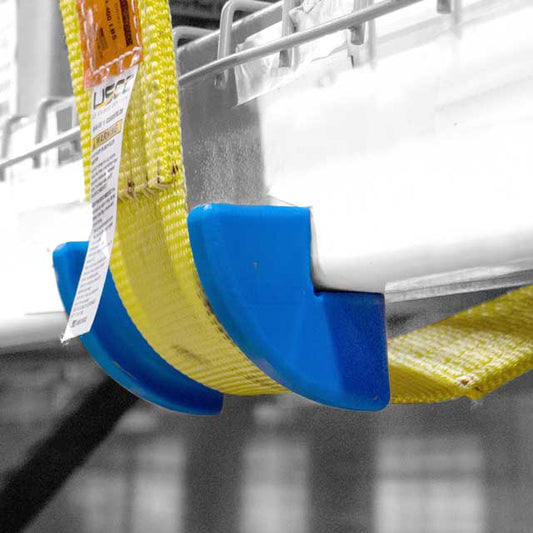

Chain Sling Protection

"Slings in contact with edges, corners, protrusions, or abrasive surfaces shall be protected with a material of sufficient strength, thickness, and construction to prevent damage." - ASME B30.9 (2021) 9-5.10.4(d)

We carry heavy-duty sling protection that's specifically designed to work with lifting chain, as well as more general options to protect your sling.

Sling Chain Inspection

Before use, you should clean - removing oil and dirt that could hide damage - and inspect the sling.

Issues to look for while inspecting your sling include bent or distorted hooks and damaged, defective, or worn chain.

Chain Wear

Even with proper care, chain will eventually begin to wear over time. It's important to regularly inspect the links of overhead lifting chain for minimum allowable thickness.

Once it's worn below this measurement, it should be removed from service.

| Size of Chain | Material Diameter | Minimum Allowable Thickness (T) | ||||

| Inches | mm | Grade 80 | Grade 100 | Grade 80 | Grade 100 | |

| 9/32" | 7 | 0.274 | 0.279 | 0.239 | ||

| 3/8" | 10 | 0.392 | 0.404 | 0.342 | ||

| 1/2" | 13 | 0.51 | 0.529 | 0.443 | ||

| 5/8" | 16 | 0.63 | 0.625 | 0.546 | ||

| 3/4" | 20 | 0.781 | - | 0.687 | - | |

| 7/8" | 22 | 0.906 | - | 0.75 | - | |

| 1" | 26 | 1.032 | - | 0.887 | - | |

| 1-1/4" | 32 | 1.25 | - | 1.091 | - | |

Heat's Effect on Chain Slings

While sling chain is considered extremely strong and durable, excessive heat can have an effect on the working load limit. Chain lifting slings used in excess of 400 degrees will experience a reduction in strength, both during exposure time and after exposure. See guidelines below.

| Grade 80 | Grade 100 | |||

|

Temperature (F) |

Reduction of Working Load Limit While at Temperature | Reduction of Working Load Limit After Exposure at Temperature | Reduction of Working Load Limit While at Temperature | Reduction of Working Load Limit After Exposure at Temperature |

| Below 400 | None | None | None | None |

| 400 | 10% | None | 15% | None |

| 500 | 15% | None | 25% | 5% |

| 600 | 20% | 5% | 20% | 15% |

| 700 | 30% | 10% | 40% | 20% |

| 800 | 40% | 15% | 50% | 25% |

| 900 | 50% | 20% | 60% | 30% |

| 1000 | 60% | 25% | 70% | 35% |

| Above 1000 | OSHA 1910.184 requires all slings exposed to temperatures above 1000 F to be removed from service | |||

NOTE: OSHA 1910.184 requires all slings exposed to temperatures over 1000º F to be removed from service.

Standard Sling Designations

Most chain slings generally consist of a master link, a chain leg or legs, and a fitting such as a hoist hook. Sling manufacturers have a standardized designation that uses a three letter combination.

- The first letter indicates the number of legs: S=Single Leg, D=Double Leg, T=Triple Leg, Q=Quadruple Leg, C=Single leg with normal chain link on the end with no fitting.

- The second letter indicates the type of master link: O=Oblong Master Link, P=Pear Shaped Master Link, S=Sling Hook, G=Grab Hook.

- The third letter indicates the style of hook: S=Sling Hook, G=Grab Hook, F=Foundry Hook, L=Latchlock Hook, O=Oblong Link

For example, a sling with designation SOG has a single leg (Letter S), with an Oblong Master Link (Letter O) and a Grab Hook (Letter G).

Each component of the chain sling's configuration can affect the working load limit and break strength. To ensure it's easy to locate this information for each chain, they come with a metal ID tag attached that is stamped with the following information:

- Sling style

- Serial number

- Chain size and grade

- Length

- Working load limit at degree of lift

Proof Testing

Proof testing is done on every link of chain to ensure its working load limit. If you order a custom chain sling, you must request proof testing when the order is placed. This testing is done for an additional fee and includes a testing certificate.

All of our chain meets or exceeds the latest guidelines of the National Association of Chain Manufacturers (NACM), ANSI B30.9 standards and OSHA specifications.

Other Lifting Slings

Overhead lifting chain slings are ideal for a range of heavy duty lifting jobs. If your application requires a different qualities, such as flexibility or stretch, see our entire selection of lifting slings, which includes fabric such as nylon and polyester, as well as heavy-duty wire.

Questions?

If you need help selecting a chain sling, see our How to Choose a Lifting Sling page or call our product specialists. They’ll be happy to any answer questions you have.

Looking for chain for tie down applications? Check out our transport chain and binders page.