What is Shoring Beam Decking?

Shoring beams have many uses for enclosed van trailer haulers, but their best use is to create additional space inside the van, otherwise known as "decking." This is a popular option for those looking to increase storage capacity and allow for a more organized, secure way to store cargo and other items while on the road.

We explain more about shoring beam decking, its benefits, and what tools you need to do this successfully.

What is Shoring Beam Decking?

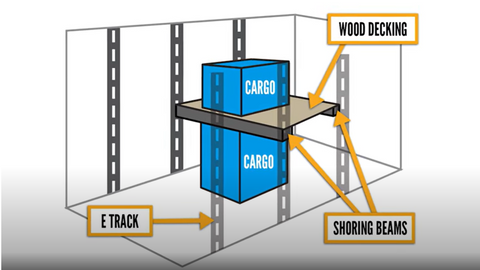

Shoring beam decking is a method used by enclosed van haulers that involves installing shoring beams in a horizontal orientation across the length of the trailer to create a platform, or second level, of storage space that would normally go unused. These shoring beams attach to the walls of the trailer via E-Track and adjust according to the trailer's width, allowing for customization to fit specific cargo needs.

Benefits of Shoring Beam Decking

Using shoring beams to create a second level in your enclosed trailer has many benefits that make hauling cargo and other items a breeze:

-

Additional Storage. Adding a second level of storage allows for better organization and utilization of space. This is especially useful when you need to transport a large number of items. Make fewer trips using more space that was previously left empty.

-

Keeps Cargo in Place. Shoring beam decking creates a solid base for your items, minimizing the risk of damage from shifting or sliding during transit. Especially for delicate or fragile items, the added stability provided by shoring beam decking ensures that they stay locked in place, reducing the potential for damage caused by rough driving or sudden stops.

-

Improve Transport Safety. Using shoring beams in non-decking applications reduces the risk of cargo shifting and damaged cargo. For heavier items that could cause serious injury if they were to fall, shoring beams act as a barrier to keep them steady and in place.

- Easy to Install. Most decking beams have E-track attachments that connect to rails installed on the walls of enclosed trailers. Make sure you install your E-Track appropriately so you have the most universal configuration if you haul different-sized loads.

How to Create Decking with Shoring Beams

Before creating shoring beam decking inside your enclosed trailer, consider the following: First, how many items do you plan to haul, and will they be large or bulky? Second, how heavy will your cargo generally be? You'll want to ensure you don't use shoring beams beyond their working load limits. Lastly, you need to know the width of your enclosed trailer to find the right length of shoring beams. Adjustable shoring beams extend beyond their initial length, but it's still important to choose one that fits appropriately.

Using shoring beams to create decking is a simple process, as listed below:

1. Install E-Track Rails

If you don't have E-track currently inside your trailer, then you need to install these rails before attempting to create decking. E-track is one of the easiest and most flexible options for enclosed trailers when it comes to using shoring beams. Most shoring beams are also made with E-Track end fittings for quick and easy attachment/detachment.

- WATCH: How to Install E-Track

The decision will be whether you install the E-Track rails vertically or horizontally. Horizontal rails work to keep taller cargo in place during transportation. They are installed along the height of the trailer walls, with multiple rails generally installed to haul additional tall cargo. Vertical railing, on the other hand, extends the length of the trailer walls and is generally installed in the central part of these walls.

Regardless, both horizontal and vertical E-Track can work to create shoring beam decking. However, your configuration depends on what you plan to haul consistently.

2. Attach Shoring Beams to the E-Track

After installing the E-Track on your enclosed trailer walls, attach your shoring beams to the rail. Adjustable shoring beams from U.S. Cargo Control are made with E-Track fittings that snap into the rail and release easily at the switch of a spring trigger!

- Check out our other E-Track accessories today!

3. Create Decking

Depending on what you want to haul in your enclosed trailer, try securing pieces of plywood or other sturdy, flat surfaces onto your attached shoring beams. This creates your second level of storage that allows you to stack your cargo items and utilize the empty space that you couldn't use before. Make sure whatever item you use as your platform won't break or bend under the weight of your cargo.

You can also create different decking configurations using your shoring beams. Try attaching them closer together to store items like spare tires.

Watch: How to Create Decking with Shoring Beams

Shoring Beams from U.S. Cargo Control

Shoring beams from U.S. Cargo Control provide added support to your enclosed van cargo that keeps everything safe and in place during transit. Also known as decking beams, they are designed to be extremely durable and able to withstand the weight of heavy cargo. With many different ways to use these items, shoring beams are the preferred tool that creates additional space, supports heavier cargo items, and is both practical and cost-effective.

These load bars are available in two different makes:

- Steel Shoring Beams: This is a solid and affordable option that adjusts to accommodate the width of various enclosed van trailers. With a 1,500 lbs. working load limit, these are reliable shoring beams that keep your cargo secure and provide a solid basis for shoring beam decking.

- Aluminum Shoring Beams: For a stronger alternative, try our aluminum shoring beams that have a 2,200 lbs. working load limit. These load bars are also adjustable to fit the width of your enclosed van trailer.

For decking applications, try shoring beams with a flat side latch. This latching mechanism stays out of the way and is safe from dents or bending during decking applications.

Watch: Shoring Beam Side Latch for Decking Applications

Other options include cargo bars that use tensioning to extend and tighten to create a support barrier to keep cargo in place. These are made with rubber non-slip pads and extend using a ratcheting component. If you want something solid to work in the back of your pickup truck or the hatchback of our SUV, then try these bars instead.

Other Moving Supplies

For hauling cargo in enclosed van trailers, make sure you have the right supplies for a safe and easy delivery. Secure your cargo items with E-Track straps that tie down your items for safer hauling. You can also provide additional padding and protection for your items, whether they are bulky or fragile, with our moving blankets and furniture covers. Lastly, take more of the bodily strain out of loading cargo with our hand trucks and moving dollies!

- Browse through more of our Moving Supplies today!

More Articles You May Like

9 E-Track Kits for Your Tie Down Needs

Dunnage Bags from U.S. Cargo Control

How to Install E-Track on a Flat Trailer

Void Size: What It Means for Dunnage Bags