2" Crosby® Bolt Type Anchor Shackle | G-2130 - 35 Ton

2" Crosby® Bolt Type Anchor Shackle | G-2130 - 35 Ton!

2" Crosby® Bolt Type Anchor Shackle | G-2130 - 35 Ton

Shackle Sizes:

Blazing Fast Shipments

Shipping & ReturnsTailored Business Programs

Partner with UsQuestions? Need it custom?

We Can Help!Payment Options

Specifications

Alloy Steel Bolt

Crosby® 35 Ton Bolt Type Anchor Shackles

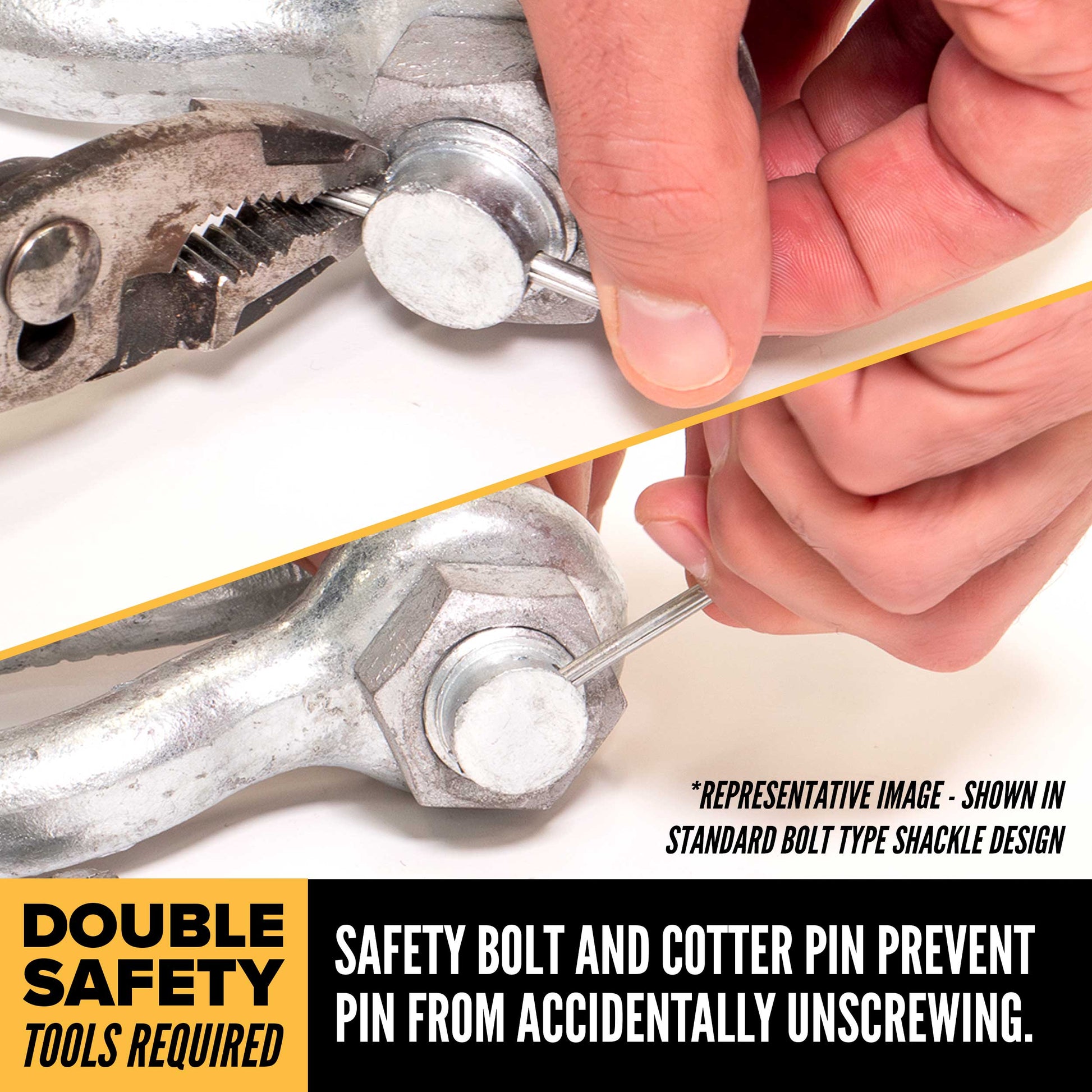

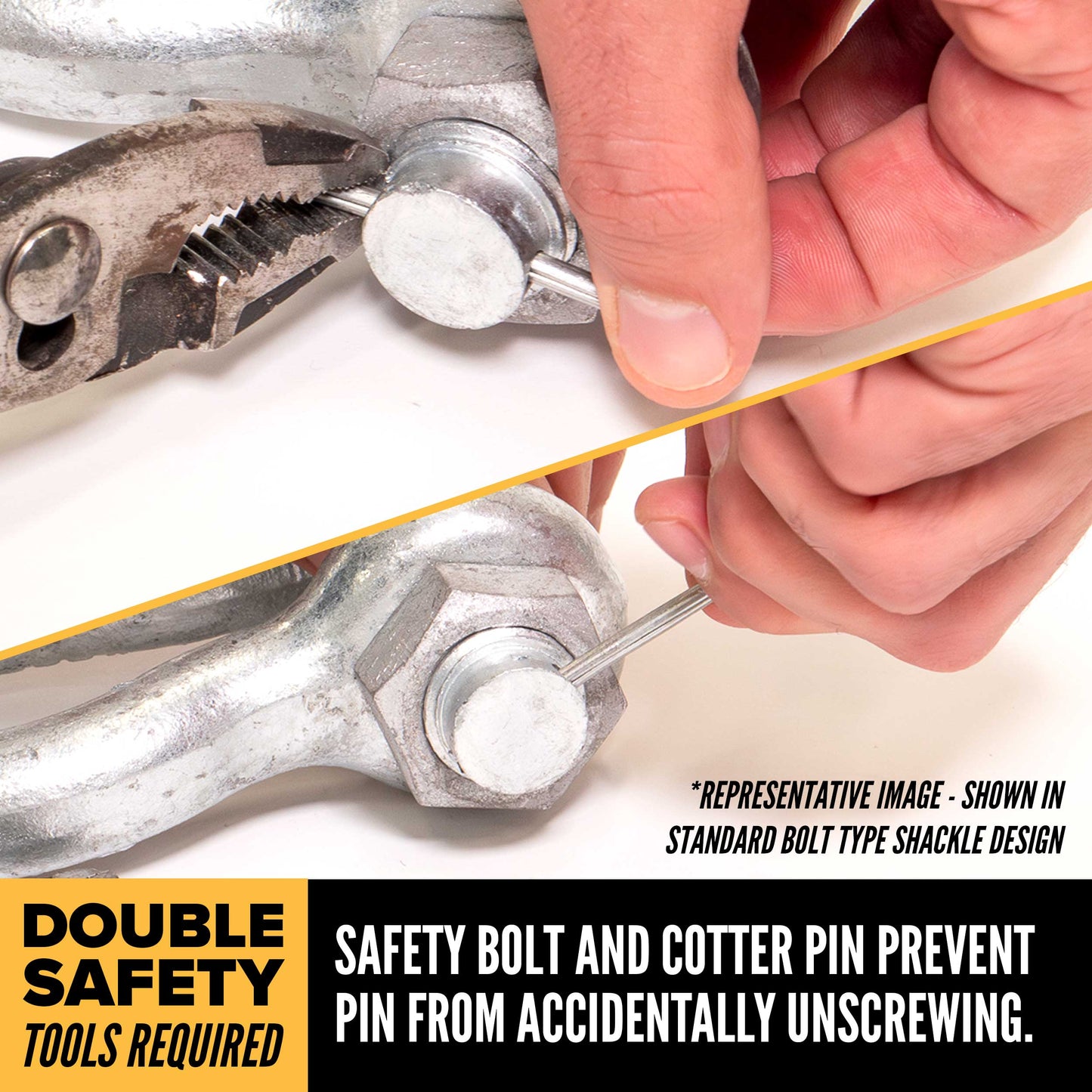

USA-made Crosby® bolt type shackles are manufactured with a thin head bolt with nut/cotter pin combination. Quenched and tempered forged steel with an alloy bolt for superior strength; hot dipped galvanization adds a layer of protection from corrosive elements.

Why Choose Bolt Type Anchor Shackles?

Bolt type anchor shackles are intended for long-term installation or permanent installation, or if there’s a risk of a load sliding on the shackle pin, which can cause it to rotate. The bolt style system prevents sliding loads from turning and backing the pin out of the shackle. Anchor bow shackles have a wider shape than D shaped shackles and are mainly used on multi-leg rigging systems.

G-2130 Shackle Features

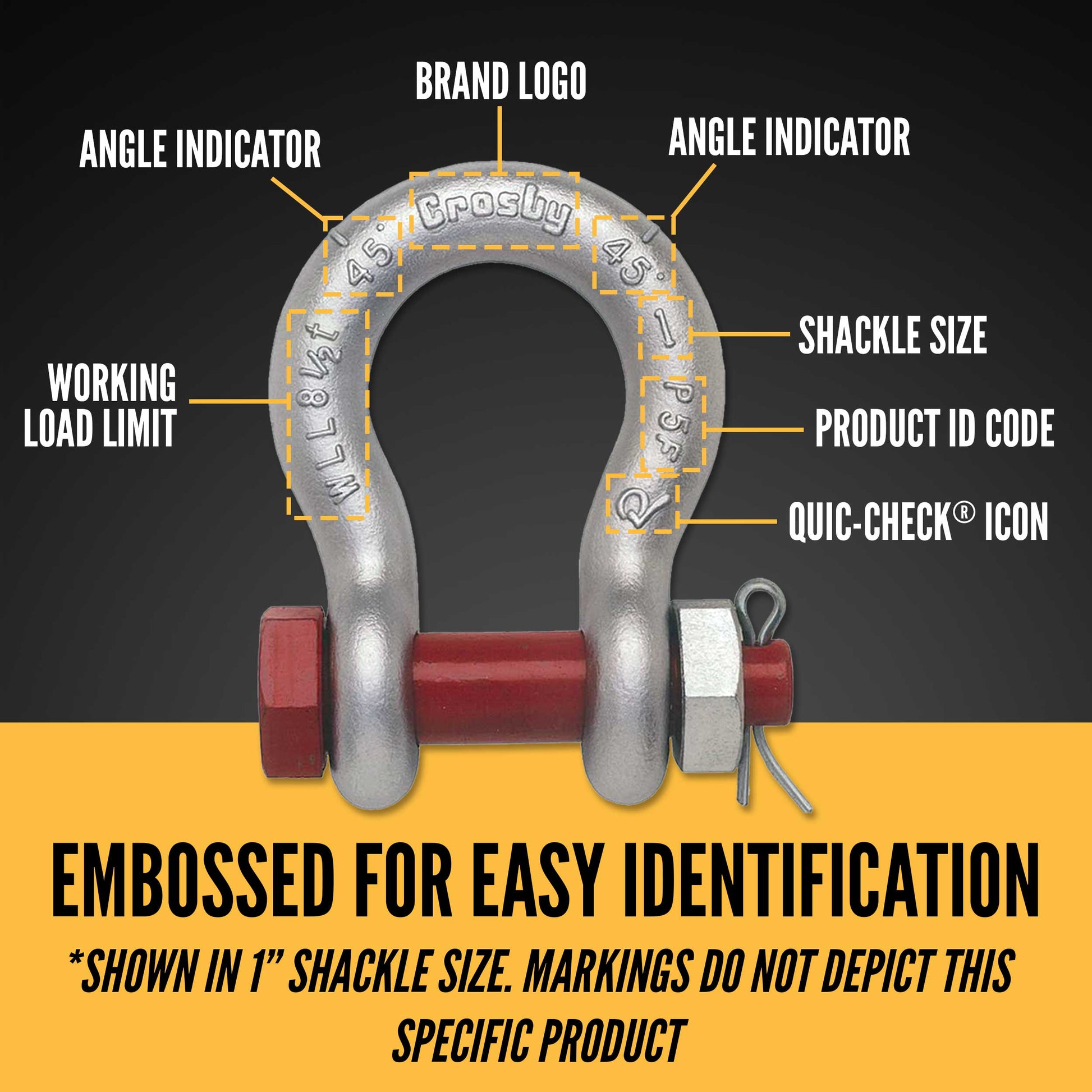

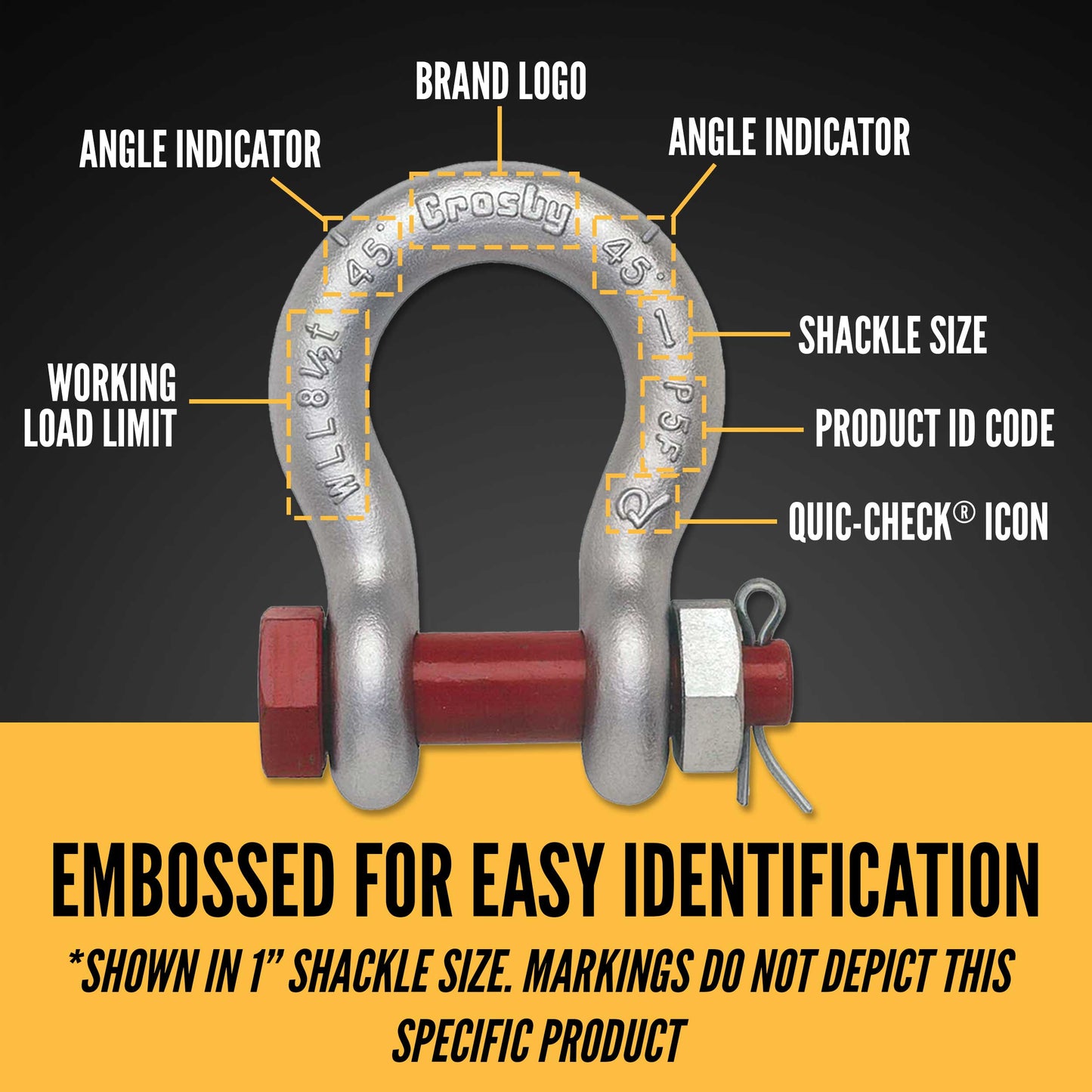

- Working load limit, Grade 6, PIC, and Crosby name on every shackle.

- Fatigue rated to 20,000 cycles at 1-1/2 times the WLL.

- Approved for use at temperatures between -40°F / -40°C and 400°F / 204°C.

Looking for other lifting and rigging products? Our wide selection includes lifting slings, turnbuckles, eye bolts, and more.

California Residents: WARNING

Add the Essentials

Complete your order with these essentials, compatible with:

2" Crosby® Bolt Type Anchor Shackle | G-2130 - 35 Ton

-

Uncompromising Quality, Always Compliant

We only source the best shackles when it comes to quality so you can have peace of mind on the job site. All of our shackles are compliant and meet or exceed the required standards to keep your job moving.

-

We're an authorized crosby distributor

Shop all CrosbyOne of the leading manufacturers in the industry and trusted name for more than a century - Crosby delivers innovation and uncompromising quality to exceed the industry's toughest demands for rigging, lifting, and material handling applications.

-

Longtime SC&RA Members

View all MembershipsWe've been active SC&RA members since 2014. With several members of our team participating in, and being members of the association, we share their commitment to safety and compliancy.

They are installed and working well

I know these cost more than the imports. If you need these to perform, trust no other. These are 100% USA made forged & tested. Threads on bolt & nut are deep, and mate well, no slop. It’s apparent they are cut from full diameter rod & not cast threads like import.

The imports have a lot of slop / between nut & bolt (nut wobbles on the threads). The imports nut & bolt only start to grab the threads 1/2 way up the threads, where as the Crosby engage instantly, right at the beginning of the thread, full contact with Crosby. Quality is consistent between Crosby shackles. Imports are sometimes mis shaped, porous surface. I work in the oilfield, many crane & fork lift loads moved daily. Not a single failure from a Crosby shackle.