Understanding Tensile Strength for Lifting & Rigging Equipment

Tensile strength can be traced to materials and items used within the lifting and rigging industries. As a means of calculating force, the tensile strength measures the amount of tension an item endures before it breaks. This metric plays a vital role in determining the maximum load capacity of various lifting devices and is a key aspect of their overall reliability.

When it comes to lifting heavy objects, whether it's in a manufacturing facility, construction site, or even your own garage, safety should always be the top priority. One crucial factor to consider in ensuring safety is understanding the tensile strength of the lifting equipment you use.

Read on to learn more about tensile strength, why it matters for lifting and rigging, and how to ensure your equipment meets the required standards for your specific tasks.

What is Tensile Strength?

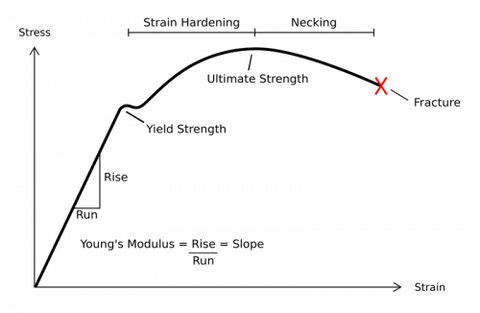

Tensile strength measures the ability of a material to withstand a pulling (tensile) force without breaking or deforming. Also called ultimate tensile strength, this point indicates the maximum amount of stress a material can endure before its deformation, as noted by the Stress-Strain graph below:

Graphic from AutoDesk.

Graphic from AutoDesk.

During tensile tests, an object held by two clamps is pulled on both ends to measure the strength of its material used. As the pulling continues, constant strain is applied to the object, up to the point where the material breaks (common for brittle materials) or hits a point where the object begins to stretch (common for ductile materials). This point of stretching is referred to as the yield strength.

Tensile Strength vs. Yield Strength

Tensile strength and yield strength mean two very different things. As constant stress and strain proportionally rise, eventually the object hits a stress point. This happens when too much pulling begins to increase the strain and change the crystalline features of the object. Minimal stress continues as strain increases, going beyond the proportional elasticity and creating a sort of rounded peak known as the yield strength.

Ultimate tensile strength is reached through a process called "strain hardening," where continued stress pulls on the elastic object before it begins to change its shape entirely. The increase in stress is due to the hardening of the material itself, which becomes stronger than its original, "un-stressed" composition. As a result, the graph starts to increase before topping out at the ultimate tensile point.

Tensile Strength vs. Break Strength

Similarly, tensile strength and break strength mean two separate things. After reaching the ultimate tensile point of an object, further stretching results in "necking," or when the localized cross-sectional area of an object begins to reduce dramatically, creating a sort of neck-like feature. Once necking occurs, stress dramatically reduces as strain continues on the object, up to the point of breaking. The time to reach the object's break strength from its ultimate tensile strength is very quick.

Tensile Strength for Lifting Equipment

In the context of lifting equipment, tensile strength plays a critical role. Ensuring that the lifting equipment has sufficient strength is essential for the safety of both personnel and property. Overloading lifting equipment can result in catastrophic failures, causing injuries, damage, or even loss of life.

Testing the ultimate tensile strength of equipment, such as lifting slings, allows workers to make informed decisions about the load it can handle efficiently. This knowledge helps optimize their lifting operations and prevent overloading, depending on the type of material used:

-

Wire & Chain: With durable lifting equipment such as chain slings or wire rope slings, the rigidity of the metal components provides a heightened tensile strength to handle heavier loads with stronger pulling forces. The material composition of metal slings holds up better in comparison to other fibrous lifting sling options.

- Webbing: Synthetic lifting slings offer more flexibility by design. Their materials cater to lightweight lifting solutions compared to wire and chain solutions. With some materials having more of a natural give than others - in this case, nylon slings stretching more than polyester slings - the tensile strength tends to be much lower than their more rigid counterparts.

Tensile Strength for Rigging Equipment

The same rules apply to rigging supplies. Rigging applications involve the same pulling forces as lifting applications, so different materials used will have various tensile strengths. Ultimately, it comes down to choosing rigid materials (wire rope and chain) or synthetic materials (nylon and polyester).

-

Chain: In some rigging applications, chains are used as lifting or securing elements. Just like wire ropes, chains have a specified tensile strength that indicates their ability to handle heavy loads safely. Chain slings, for example, must have a sufficient strength to support the intended load.

-

Hooks and Shackles: Rigging hooks and shackles are critical connecting components in rigging setups. They are used to attach the load to the lifting equipment. These components are typically made from materials with high tensile strength, such as alloy steel. The tensile strength of hooks and shackles ensures that they can withstand the forces generated during lifting without failure.

- Turnbuckles: Turnbuckles tension wire rope, chain, and other support lines in rigging, architecture, and marine applications. Fashioned with two threaded rods fitted with specific attachments, turnbuckles consist of metal and carry a range of tensile strengths depending on their sizes and makes. For a device such as this, higher tensile strengths are required in order for it to function.

Safe Usage of Lifting & Rigging Equipment

No matter what application you choose, tensile strength is important for both lifting and rigging equipment. While this is a critical metric to consider for the material used, keep in mind that other components, such as rigging hardware, contain varying break strengths and that the lowest strength in the entire system is the one you should be working off of to prevent system failure.

That being said, it's important to follow these guidelines with your equipment:

-

Stay Compliant: Various regulations and industry standards govern the use of lifting equipment. Complying with these standards is not only a legal requirement but also a means of ensuring that your equipment is up to the task and safe for use.

- Do Regular Inspections and Maintenance: Regular inspections and maintenance of rigging equipment ensure maintenance of the tensile strength and overall integrity of the components. Over time, wear and tear, corrosion, or damage can reduce the effectiveness of rigging equipment and its tensile strength.

Contact our product experts for any questions you have on tensile strength, as well as the lifting and rigging products we carry.

More Articles You May Like:

ABC's of Fall Protection and Fall Arrest Systems

How to Tell When It's Time For New Rigging Gear

Key Factors to Having an In-House Test Bed

Which Lifting Clamp is Right for Me?