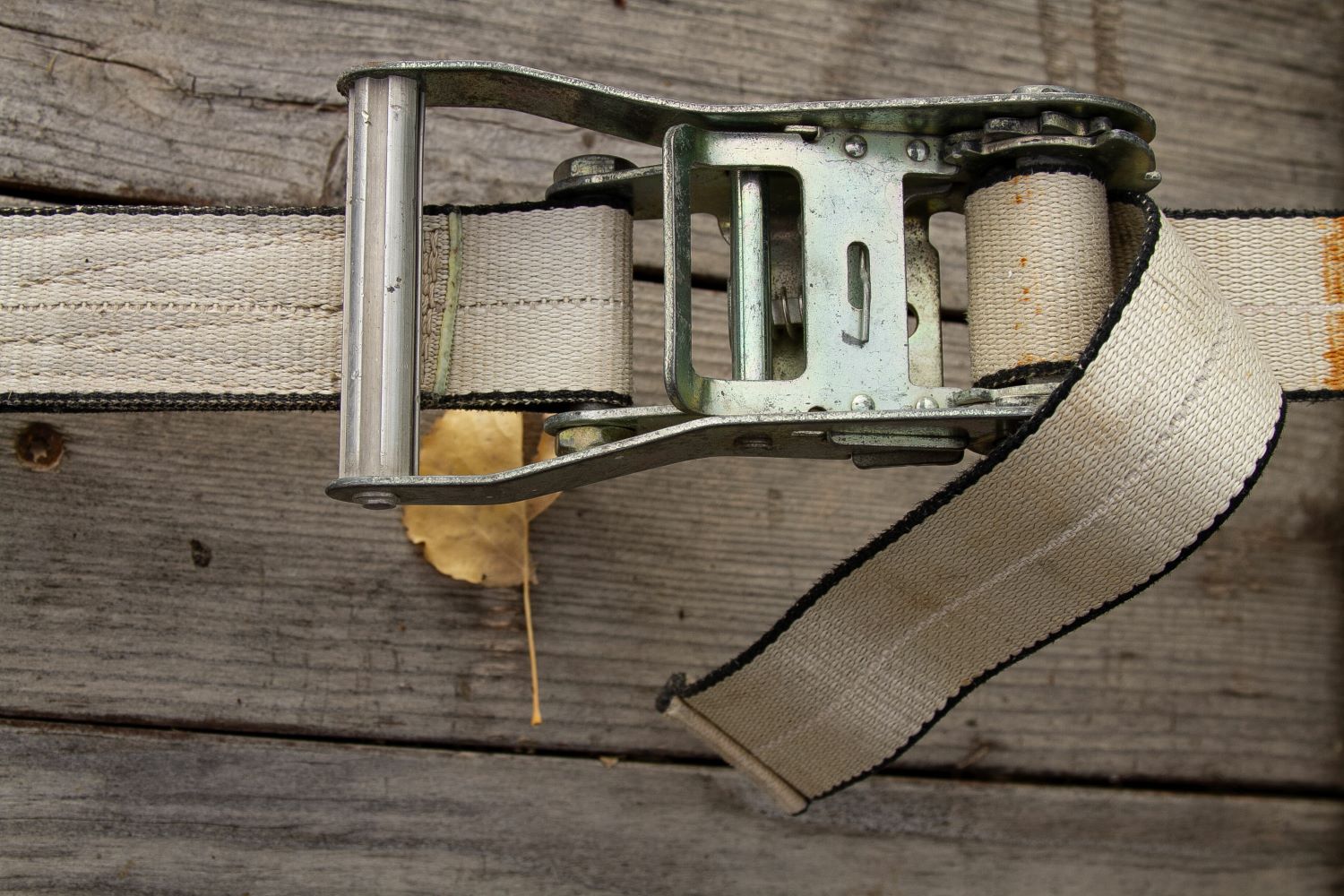

2" x 15' Endless Loop Ratchet Strap Tie Down

An endless ratchet strap is designed without a hook or other hardware on one end, so it can be wrapped around a load and fed back through the ratchet to tighten and secure, making them ideal for bundling and packaging. Because the loop design is so simple, it works well for a wide variety of cargo, from lumber and piping securement to smaller product bundling or keeping boxes together on a pallet. You can trust that your cargo gets from point A to point B held together.

The wide-handled ratchet has a zinc-plating for corrosion-resistance and is easy to grip so you can achieve the optimal strap tension.

The yarn used to make our webbing is slightly thicker than that offered by most competitors, with more picks per inch used to create each strap. It's also heat-sealed on the end. Together, these features provide better resistance to abrasion, tearing, and cutting, so your ratchet straps will last longer.

Corrosion-Resistant Ratchet Characteristics

Zinc-coated ratchet component has a short, wide handle for working in tight spaces.

Compliant with Industry Standards

All of our ratchet straps are tagged with the working load limit to meet FMCSA and DOT regulations, CVSA and WSTDA guidelines, and North American Cargo Securement standards.

Learn more about proper load handling and securement in the WSTDA safety bulletins.

Custom Ratchet Straps Available

Looking for a combination of length, color, hardware you don't see on the website? Want straps stenciled with your company name or logo? We also offer custom tie down straps. We can create the ideal strap for your application at our Iowa manufacturing facility - this not only allows us to hold all of our straps to the same high quality standards, but it also means fast shipping to you!

WSTDA Ratchet Use Guidelines

According to the WSTDA (section 4.6.8): "When using web tie downs with a winch or ratchet, a minimum of 2 and a maximum of 4 wraps of webbing shall be wound on the winch or ratchet mandrel. Excessive wraps of webbing on the mandrel may reduce the working load limit (WLL) of the web tie down and may interfere with proper operation."

Additionally, they define design factor as the "ratio of the breaking strength to the working load limit." The design factor is 3:1 for these tie down straps to build in a level of redundancy, accounting for unknown factors to keep you, your crew, and those around you safe.

Comprehensive Cargo Securement Supplies

Complete your tie down system with strap protection, D-rings, corner protectors, and more. We also offer transport chains and binders as an alternative tie-down solution, as well as an ergonomic Good-N-Tight ratchet strap tightening handle.

California Residents: WARNING