$50 off $500 with code MAY50 + $99 Free Shipping

Lifting Links & Rigging Rings

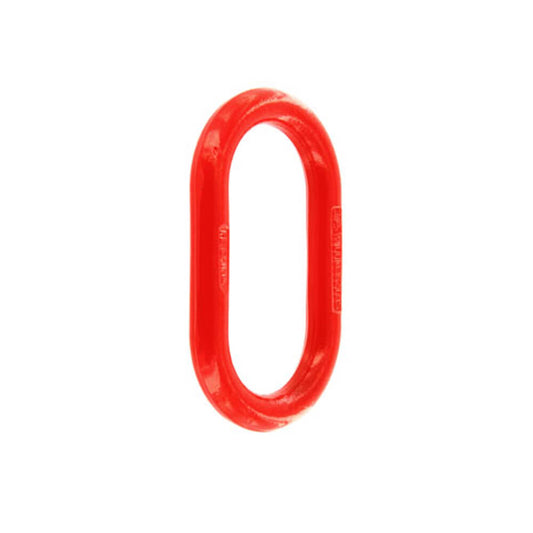

Heavy-Duty Lifting Links and Rigging Rings

Add strength and reliability to your lifting operations with our top-tier rigging solutions. We offer a comprehensive range of lifting links and rigging rings designed to meet the highest standards of performance and safety.

Whether you’re rigging a load on a construction site, coordinating a heavy lift in a shipping yard, or assembling a multi-leg chain sling, these essential components provide the secure connection points your crew counts on. We carry a full lineup of master links, sub-assemblies, and stainless steel rigging rings engineered for strength, safety, and performance under load.

What are Lifting Links and Rigging Rings?

Both play a similar role in lifting assemblies but are available in different configurations.

Rigging Master Links

Lifting links are connectors designed to be used with chain slings, wire rope slings, or synthetic slings in overhead lifting. These links form the critical connection between lifting slings and crane hooks or spreader beams.

Available in grades 80, 100, and 120, our rigging master links are engineered to meet and exceed industry expectations.

Rigging Rings

Often circular or shaped for specific load paths, our rigging rings are made from type 304 stainless steel. Their smooth contours allow for reliable movement without cutting into sling material or compromising structural integrity.

Common Uses for Lifting Links

These components are the workhorses of the rigging world. You'll find them used in chain slings, wire rope sling and synthetic sling connections, loading balancing applications, crane and hoist rigging, and more.

How to Choose the Right Lifting Link or Rigging Ring

To ensure safety and efficiency, make sure you are considering the most important factors before purchasing:

- Load Weight & Type: Make sure the working load limit of the link you choose is greater than the weight of your load

- Sling Configuration: The type of master link you need is dependent on the number of legs your sling has. Sub-assemblies, for example, are best-suited for multi-leg chain slings due to the included sub-links.

- Hook Compatibility: Make sure the size and throat opening of your crane or lifting hook can accommodate the diameter of your rigging ring.

- Environmental Factors: For example, if you'll be exposing your lifting assembly to moisture, choose a configuration with corrosion-resistance.

Maintenance and Inspection Tips

Before each lift, you should inspect your rigging gear to ensure it remains in safe, working condition:

- Look for signs of wear, stretching, corrosion, or cracks.

- Keep a log of inspections, including dimensional checks against original specs.

- Remove any component from service if it shows signs of deformity, excessive wear, or damage.

Questions?

Not sure which lifting link or rigging ring is the right choice for you? Need more information on our master link grades? Call to speak to one of our product experts today to learn more. They can answer any questions you may have and can even help you place an order!

We offer a wide variety of other rigging hardware as well, including connecting links, lifting rings, rigging shackles, turnbuckles, and more!