How to Use Plate Clamps Safely and Effectively

Plate clamps, or sheet clamps, make difficult lifts safer and easier. While these strong lifting tools allow for faster production speeds, they should not be used haphazardly. The use of plate lifting clamps requires an operator who is trained on their use and who takes safety seriously.

Remember to always position the plate clamp over the center of gravity to maximize control.

Remember to always position the plate clamp over the center of gravity to maximize control.

This Crosby® IPNM10P non-marring lifting clamp lifts plates without damage or scratching

You also need to pay close attention to the max jaw capacity of the plate clamp. Jaw capacity should be as close as possible to the thickness of the material you're lifting. Lastly, you should not be lifting plates that have a surface that is harder than the teeth of the clamp. For plates that have an extremely hard surface or a surface which could be easily damaged, there are certain types of lifting clamps that have a non-marring jaw and no teeth. Examples of this are the Crosby® IPNM10 Lifting Clamps and the Terrier TNMK/TNMKA Lifting Clamps.

This Crosby® IPNM10P non-marring lifting clamp lifts plates without damage or scratching

You also need to pay close attention to the max jaw capacity of the plate clamp. Jaw capacity should be as close as possible to the thickness of the material you're lifting. Lastly, you should not be lifting plates that have a surface that is harder than the teeth of the clamp. For plates that have an extremely hard surface or a surface which could be easily damaged, there are certain types of lifting clamps that have a non-marring jaw and no teeth. Examples of this are the Crosby® IPNM10 Lifting Clamps and the Terrier TNMK/TNMKA Lifting Clamps.

Spreader bars like this one are ideal for lifting long plates.

Just as their name suggests, horizontal lifting clamps are used to lift horizontal objects. If you are lifting a long plate horizontally, never use a quad sling. This will cause the horizontal clamps to turn and potentially slip off. Instead, use a spreader bar with double-leg slings that connect to the plate clamp. When it comes to lifting short plates horizontally, one double sling with horizontal plate clamps on each end will suffice. To maintain proper lifting strength and control, always ensure there is a minimum included angle of at least 90 degrees. Never use vertical plate clamps for a horizontal lift.

Spreader bars like this one are ideal for lifting long plates.

Just as their name suggests, horizontal lifting clamps are used to lift horizontal objects. If you are lifting a long plate horizontally, never use a quad sling. This will cause the horizontal clamps to turn and potentially slip off. Instead, use a spreader bar with double-leg slings that connect to the plate clamp. When it comes to lifting short plates horizontally, one double sling with horizontal plate clamps on each end will suffice. To maintain proper lifting strength and control, always ensure there is a minimum included angle of at least 90 degrees. Never use vertical plate clamps for a horizontal lift.

For full inspection instructions, refer to ASME B30.20.

As stated above, choosing the proper size and type of lifting clamp is the best way to ensure longer plate clamp life. Another thing that riggers can do to care for their plate lifting clamps is to minimize swing during the lift. Less swing results in less stress on the lifting clamp and a good crane operator knows how to minimize swing. If you have any other questions about plate clamps let us know in the comment section below.

For full inspection instructions, refer to ASME B30.20.

As stated above, choosing the proper size and type of lifting clamp is the best way to ensure longer plate clamp life. Another thing that riggers can do to care for their plate lifting clamps is to minimize swing during the lift. Less swing results in less stress on the lifting clamp and a good crane operator knows how to minimize swing. If you have any other questions about plate clamps let us know in the comment section below.

Remember to always position the plate clamp over the center of gravity to maximize control.

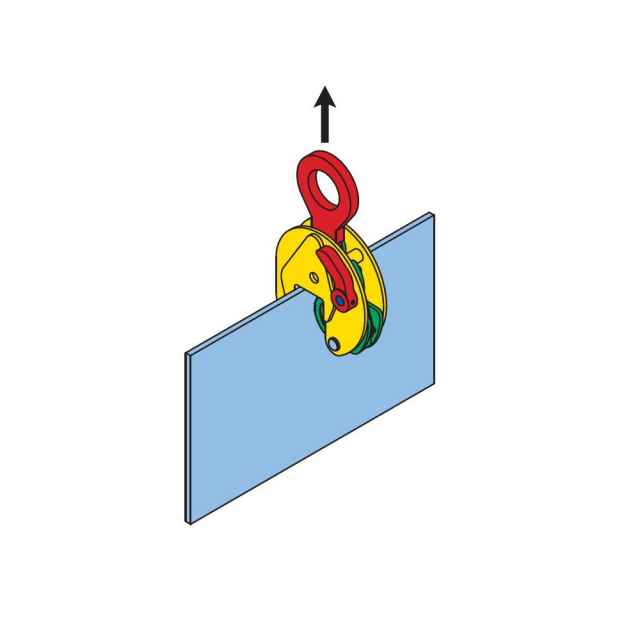

Remember to always position the plate clamp over the center of gravity to maximize control.How Plate Clamps Work

Plate clamps eliminate the need for drilling or creating a hitch. The most important parts of a plate clamp include the lifting shackle, spring, teeth within the jaw, and the various links and pins. To lift a plate, the teeth of the plate clamp need to be pushed into the plate. With help from the powerful spring, this turns the lifting point of the clamp into the lifting point of the plate and essentially causes the two objects to become one. What's great about plate clamps is that their grip strength automatically increases as the load gets heavier. Essentially, the weight of the load determines how much link tension there will be and the link tension determines jaw torque and ultimately grip strength. Learn more about what this means below.How to Pick the Proper Size and Type of Plate Clamp

Choosing the proper size plate clamp will not only maximize safety but also extend the life of the plate clamp. To do this, you should buy a clamp with the closest working load limit (WLL) to the weight of the plate being lifted. This ensures that the jaw provides optimal clamping force and penetration. Keep in mind that bigger is not always better with plate clamps. There are minimum load requirements because a load that is too light will not be able to create sufficient grip strength. That's why most plate clamps have both minimum and maximum load requirements stamped on them. It's recommended that you avoid lifting a load that's 20% below the rated capacity of the clamp. This Crosby® IPNM10P non-marring lifting clamp lifts plates without damage or scratching

This Crosby® IPNM10P non-marring lifting clamp lifts plates without damage or scratchingSafety Tips for Vertical Plate Lifting Clamps

Vertical plate lifting clamps can lift and turn over flat plates 180 degrees and can be used to transport plates in a vertical position. Vertical lifting clamps should never be sideloaded and you should never try to lift more than one plate at a time. If you're lifting a long plate, you should consider using two clamps connected to a spreader bar to minimize swing and maximize lifting safety. Also, keep in mind that plates which are hot in temperature can damage the structural integrity of the plate clamp. Columbus McKinnon recommends that you do not lift plates that are 250 degrees or higher.Safety Tips for Horizontal Plate Lifting Clamps

Spreader bars like this one are ideal for lifting long plates.

Spreader bars like this one are ideal for lifting long plates.How to Inspect and Care for Plate Clamps

Lifting clamps should be inspected every 1-4 weeks depending on use. To prevent plates from slipping, you should degrease clamps regularly and remove any grit, dirt, or mud. You should also lubricate the moving parts of the clamp, but never lubricate the teeth of a lifting clamp. Check the teeth regularly for chips and breaks. According to ASME standards, chipped teeth are only acceptable if the chip is less than half the width of the tooth and the adjoining teeth are undamaged. If there is any tooth damage beyond this, the plate lifting clamp is not safe to use. Other things to look for when inspecting plate lifting clamps include spring deformation, pad deformation, bending of hook ring, markings on top of the mouth, wear on any pins, pulling on rivets, and hook elongation. For full inspection instructions, refer to ASME B30.20.

For full inspection instructions, refer to ASME B30.20.