Hoist Hooks, Rigging Hooks, Sling Hooks & Lifting Hooks

Hooks for Lifting & Rigging

Rigging and lifting hooks, including hoist hooks, sling hooks, and more are essential for many applications, but can differ widely in design, strength, and capacity.

From small swivel eye stainless steel styles to heavy duty sling hooks with a working load limit of over 8,000 lbs., you'll find the right lifting hooks for the job at US Cargo Control.

These lifting chain hooks come in many variations, but there are general concepts that apply to most of them - we've outlined some of the basics below, and suggest contacting our sales specialists with any other questions you may have.

Lifting Hooks Attachment Options

There are two main attachment styles: eye and clevis. A popular subset of hoist hooks also include the ability to swivel.

Eye Hook

Eye hooks are the most common choice. The circular connection allows for a permanent attachment and greater flexibility compared to a clevis hook. The downside, however, is that if the hook is damaged, the whole sling will have to be retired.

Clevis Hook

Designed with a clevis and bolt or pin at the base, clevis hooks offer a secure way to fasten the hook to a bracket or chain without being permanent. They do have less range of motion than the eye hooks, but can be easily replaced.

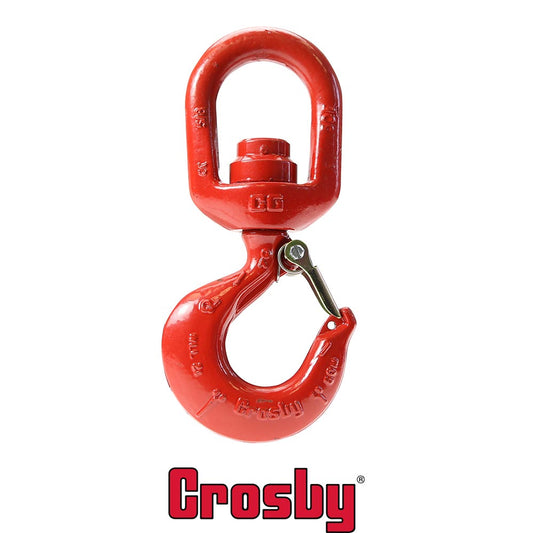

Swivel Lifting Hook

Swivel hooks allow you to rotate the hook to simplify the loading process and prevent your chain or other rigging hardware from becoming twisted. Most are only designed to be rotated before you add the load and cannot be swiveled under load.

If you need a hook that can rotate freely with a load, a swivel hook with a bearing is required, such as a Crosby L-3322B or S-3322B.

Types of Rigging Hooks

After you've chosen the attachment type that will work best for you, you'll want to further narrow down your selection by looking at hoist hook styles. There are a ton of options out there, but we'll touch on some of the most popular.

Grab Hook

Grab hooks are designed to "grab" to keep a chain from slipping off the hook. They have a narrow throat that is especially effective at holding chain.

Slip Hook

These generally have a wider throat than grab hooks. Slip hooks occasionally include a latch design to keep an attached object in its place.

Self-Locking Hook

When used within the working load limit guidelines, a self-locking design ensures the hook will not open when under heavy load.

Sorting Hook

Sorting hooks are best-suited to applications involving loads like pipes or flat plates due to their deep straight throat.

Important Terminology for Lifting Hooks

There's a lot of jargon associated with rigging hooks - learn more about the most frequently used before you start your search.

Sling Hook Grade

This indication refers to the tensile strength of metal. Grades that are approved for overhead lifting include grades 80, 100, and 120. All are made from an alloy steel and provide different levels of strength. For example, a grade 100 hook will provide an approximately 25% higher working load limit than a grade 80 hook.

Learn more about the different chain grades and their working load limits.

Type 316 Stainless Steel

This "marine grade" metal has better corrosion resistance to salts, chemicals and acids, particularly marine environments that involve immersion or spray of sea water.

Lifting Hook Finishes

The different hook finishes offer different benefits.

If the lifting hook has a galvanized finish, the metal has a thin coating of zinc to protect against rust and provide resistance to corrosion.

A powder coat finish provides corrosion-resistance as well and is generally ideal for easy identification of the different grades. Our primary selection of grade 80 hooks are all bright yellow, while our primary selection of grade 120 hooks are bright blue.

Hoist Hook Working Load Limit (WLL)

Sometimes also called rated capacity, working load limit is the maximum weight that should be applied to the item when in use.

This number is based on ideal working and environmental conditions, so if you are using the equipment in abnormal conditions (extremely high or low temperatures, chemical vapor or solution contact, immersion over time in salt water, acids, etc.), this limit may not be correct and special precautions should be taken.

*Working load limit should never be exceeded*

Break Strength

Break strength is the amount of force used when equipment was found to break during testing at the manufacturer. It's important to keep in mind that testing is done in a controlled environment with ideal conditions. Real life applications will involve different factors, forces, and environmental conditions, so it's best practice to follow the WLL guidelines, which is generally 1/3 of the break strength for lifting hooks.

A hoist hook undergoes extensive pressure, so it's important to inspect them carefully and often for damage, cracks, bending and, straightening. Hooks are often stamped with numbers to indicate the load information and rating of the device, making it easy to check the hook for integrity and any damage that might have occurred.

Questions About Hoist Hooks?

Lifting hooks come in a variety of styles and capacities for a number of uses, and you can count on US Cargo Control to offer just what you need, whether it's a small slip hook or a heavy duty clevis hook.

Don't see the lifting hook you need or aren't sure what might be the best hook for your use? Contact one of our trained sales specialists - they'll be happy to help answer your questions and even help you place an order.

Be sure to check our other lifting and rigging supplies, including shackles, snatch blocks, connecting and coupling links, chain slings, turnbuckles, and wire rope.